We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

Tools

In the world of Lean Manufacturing, we frequently hear about coaching.

Unfortunately, I have found that there is still a great deal of confusion about what coaching is and its activity entails. Often it is confused with consulting, mentoring, or training.

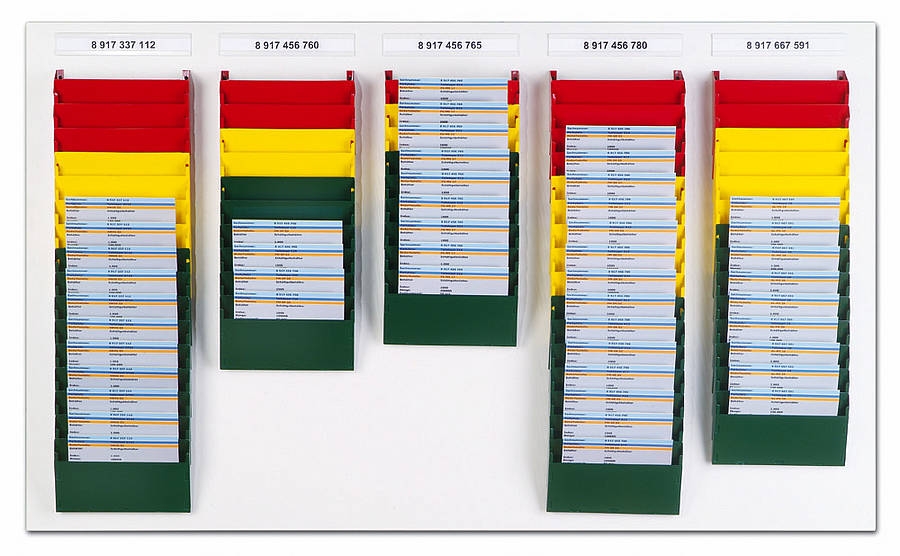

Kanban is a Japanese word meaning “signal”.

But what kind of signal?

Most of the time, this type of signal indicates two things:

1. It is time to supply.

2. It is time to produce.

Why was it invented?

Have you ever thought to buy a new car?

Every time you identified the brand, color, and other details of pertaining to your choice, you began to see it everywhere around you. The things that you didn’t notice beforehand will be visible from now on.

The guiding principle behind the "Lean Product Development Process" is the following:

Be Customer Oriented!

To meet the needs of your clients and offer them products that contains what they value most it's necessary to embrace this principle and make it real within your company culture.

In the process of implementing Lean Manufacturing culture, it is essential to know how to communicate correctly what Lean Production is.

Knowing about the way of thinking of our collaborators makes the process of communication with our listener efficient and harmonious.

Motivation is energy in movement, its effect is an impulse which runs along the nerves and makes us immediately move from the chair to get the remote control or to rush out of bed early in the morning to get to the beach or to finally do that thing we hate to do and that we have been continually postponing.

Lean Production is founded on team work; this ensures that the basic skill for launching and leading the Lean culture implementation to success is (even before all of its methods) the management of a work group. If we are unable to manage and motivate a work group, then we will never be able to implement Lean production.

If you want things and people around you to change, first of all you must change. The solutions for achieving the objectives that you set come from the quality of the questions you ask yourselves.

If we want to obtain quality solutions to our problems, we must ask ourselves quality questions, this is the essential premise for finding quality solutions.

For a few weeks now we have been witnessing some events which will probably further worsen the economic crisis currently taking place in Italy.

The devaluation of the Yuan

In an effort to return competitiveness to industry, China has devaluated its currency by 10%.

In an effort to return competitiveness to industry, China has devaluated its currency by 10%.