We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

All Our Blogs

In order to start the Kaizen improvement process, the following elements are essential:

1. The clear separation between what is considered "value" and what is considered "waste" within the given context.

2. The knowledge of the 3 types of family waste: Muda, Muri and Mura.

In the world of Lean Manufacturing, we frequently hear about coaching.

Unfortunately, I have found that there is still a great deal of confusion about what coaching is and its activity entails. Often it is confused with consulting, mentoring, or training.

I often hear companies' collaborators complaining that they are in too many unuseful meetings. By the way, today's business complexity brings in a continuous flow of information that oblige managers and middle managers to continuously review, revise, and decide correctly what is necessary to do.

To do this, they need to be in meetings...

However, I think the real reasons why people are complaining are:

Collaborators are not puppets; you can not expect they will achieve goals if you are constantly micro-managing them; if you usually do this, you end up with a lot of frustration and wasted time in controlling them.

Stop continuously checking what they are doing, how they are doing, and when they are doing it, and suggest your ideas and solutions.

Do not inhibit them.

If you are micro-managing, it is because you do not trust them and do not trust because you missed some preconditions and missed setting some frames.

In the company, it is possible to see the force of resistance to change at work just as soon as new ideas which in fact question the entire hierarchy, are introduced.

The resistance to change is much stronger the closer you get to the vertex of the company pyramid.

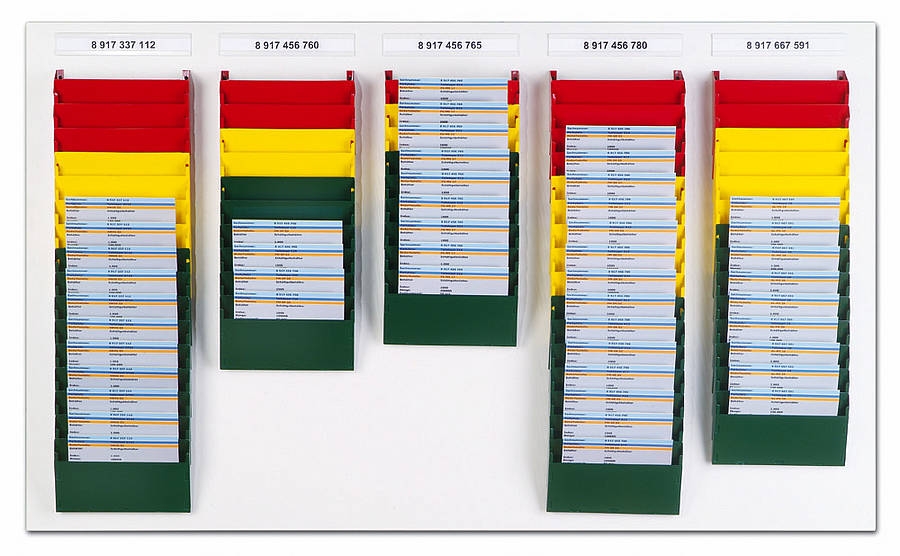

Kanban is a Japanese word meaning “signal”.

But what kind of signal?

Most of the time, this type of signal indicates two things:

1. It is time to supply.

2. It is time to produce.

Why was it invented?

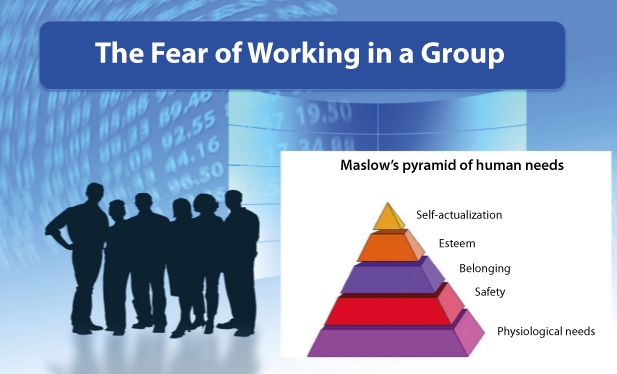

Lean Manufacturing and the Kaizen philosophy of continuous improvement are based on work groups. It is not possible to implement WCM or TPM if we are unable to manage and promote teamwork.

What are the base conditions that a good Kaizen coach must create so that the group performs very well?

Have you ever thought to buy a new car?

Every time you identified the brand, color, and other details of pertaining to your choice, you began to see it everywhere around you. The things that you didn’t notice beforehand will be visible from now on.

If we study the various graphic representations of the Toyota Production System, Just in Time, TPM and WCM, it is possible to notice that in these models there is always the recall at the involvement of all the company people.

The neverending improving work is done to get rid from wastes and to improve the value aggregation in work activities and this is the daily focus of a company that follow the Lean Production paradigm. This work can be done efficiently and with a R.O.I. only if the problem solvings workshops are always done with a 360° vision and opennes attitude about the analyzed problems; this is the basic attitude that is required and it is necessary to develop in a lean team work.