The Kaizen process: after having seen the 3 fundamental principles of the Kaizen method, let's analyze the 7 concepts that transform the Kaizen method into a highly effective operating methodology.

The Kaizen process concepts are presented in a random order, their importance and their specific weight are equal; there is no better or more important concept than another.

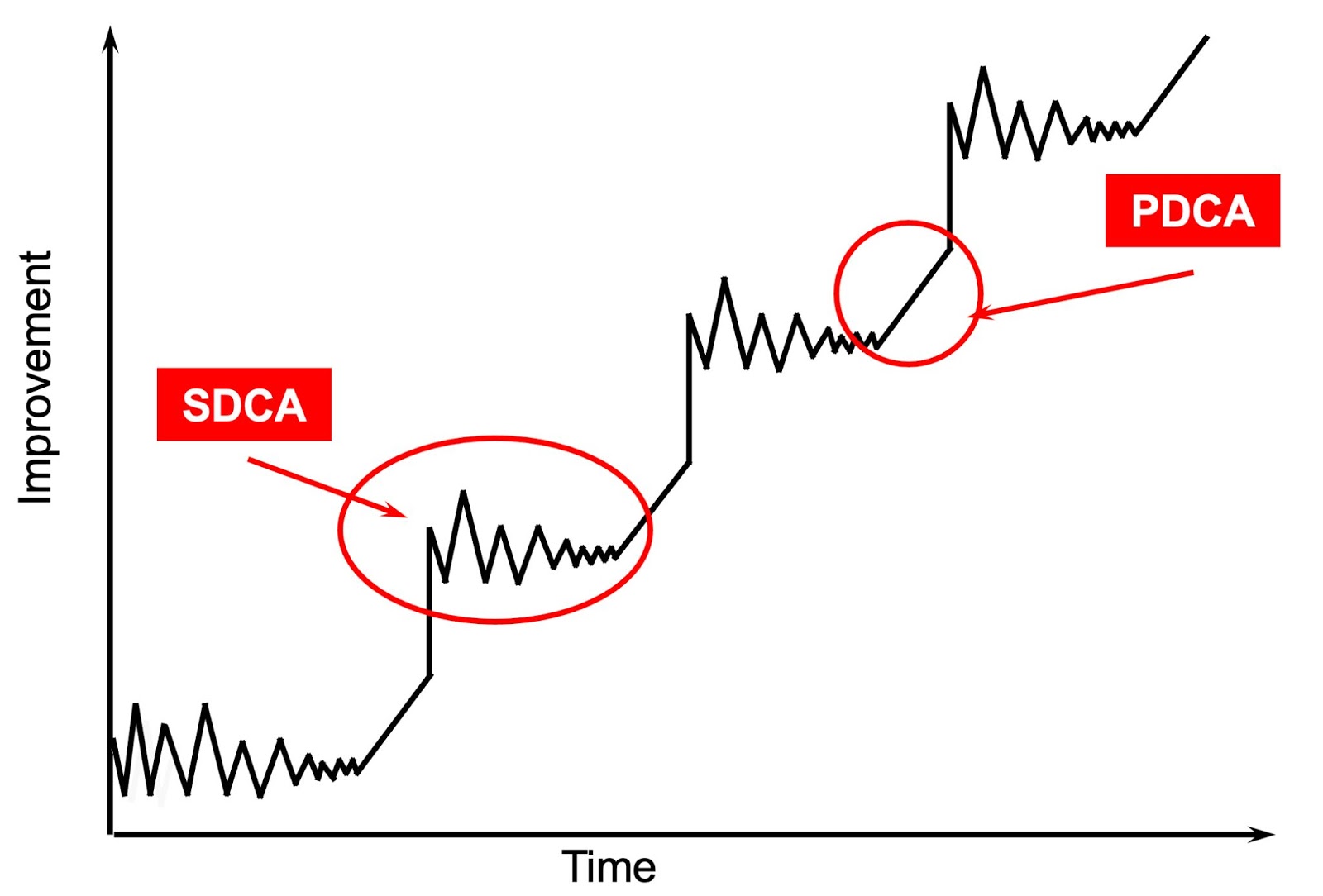

From SDCA to PDCA

This concept is based on the work developed by Edward Deming and its usefulness lies in the ability to give an operational and methodological order to the activities when we find ourselves in the need to carry out and manage change.

This concept requires that before embarking on improvements of any kind, processes that are not yielding stable results must be stabilized; once the results have been stabilized using an SDCA standardization cycle, an improvement cycle can be implemented with a PDCA improvement cycle. The P in the term PDCA means Planning and in this context it refers to improvement planning.

Both SDCA stabilization cycles and PDCA improvement cycles can be done through workshops called Kaizen Blitz.

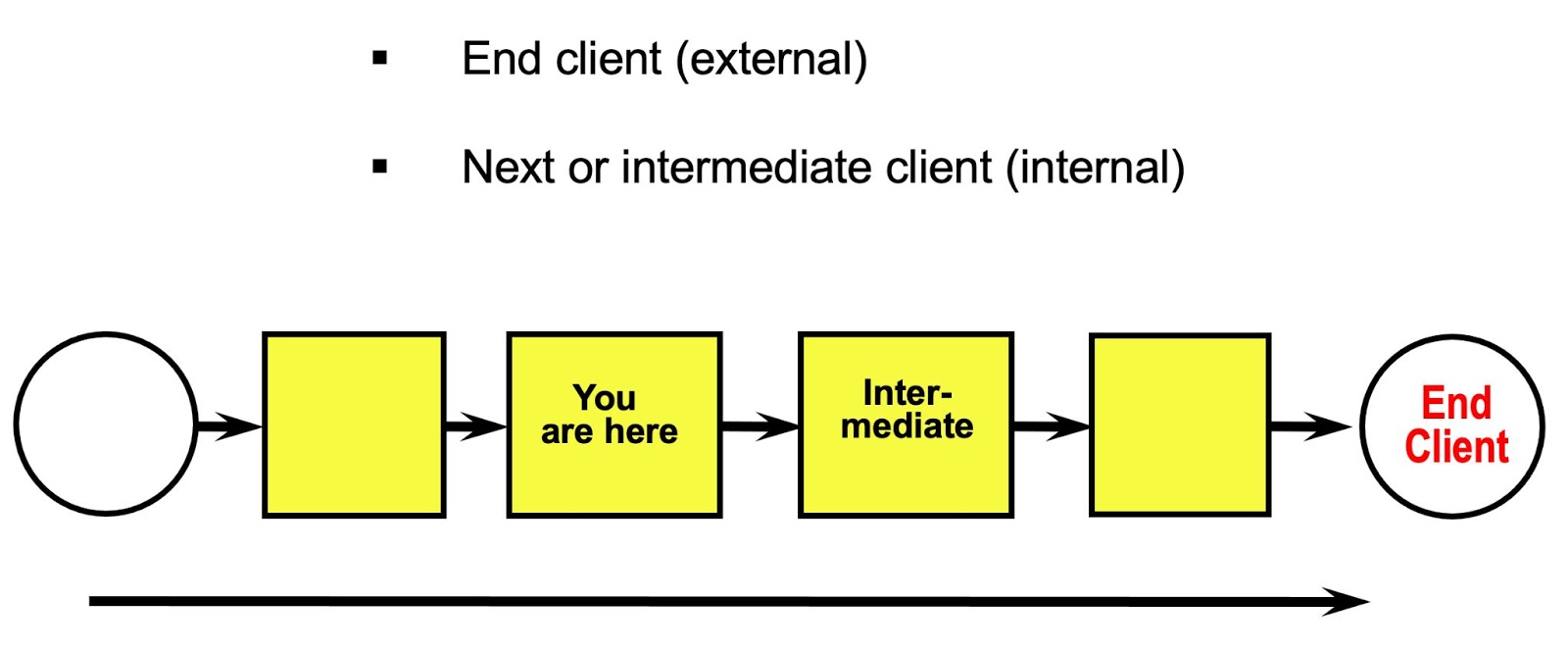

THE NEXT PROCESS IS A CUSTOMER

This concept of the Kaizen Process is fundamental to focus company employees on the right priorities. The customer in the Kaizen and Lean Manufacturing culture is the most important person and the one who must be satisfied to the best of one's ability.

This mindset is also applied to the intermediate and internal processes of the company. This means that each collaborator must put himself in the perspective of satisfying the needs of the process that comes after his own. To achieve this goal, however, it will be necessary to inform oneself in the details of the customer's needs and take action accordingly.

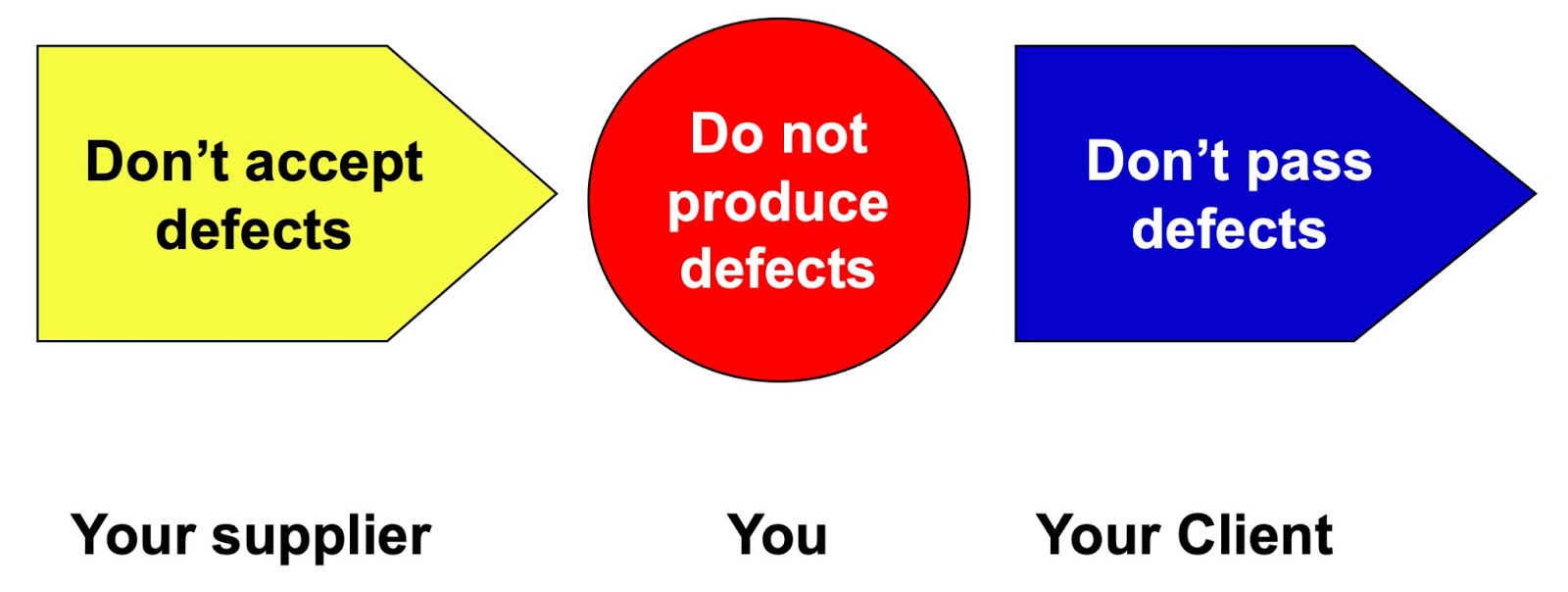

QUALITY FIRST

Quality is the most important factor in the Kaizen process.

To be sure of producing quality products and services, you just need to respect 3 simple rules. Don't get bad quality, don't produce bad quality, and don't convey bad quality.

In order not to receive, not to produce and not to transmit bad quality, the appropriate standards must be established in all 3 of these stages. To put this concept into practice, the self-quality matrix methodology is used.

MARKET ORIENTATION

Being market oriented means being focused on what our market wants and not on what we are capable of doing today.

Many companies, reaching success, remain prisoners of their own paradigms and enter in a loop of self-celebration; in the meantime the market goes on, the needs of the customers change and the competitors propose new things.

Do you recognize some of these brands?

Being market oriented can be difficult to implement when the company does not have a turnover of "fresh" human resources who can always look at the business with new eyes and do not allow themselves to be influenced by the "old guard" who does not want to change or who does want to see which change is coming. A company that embraces the kaizen process cannot fall into this mistake.

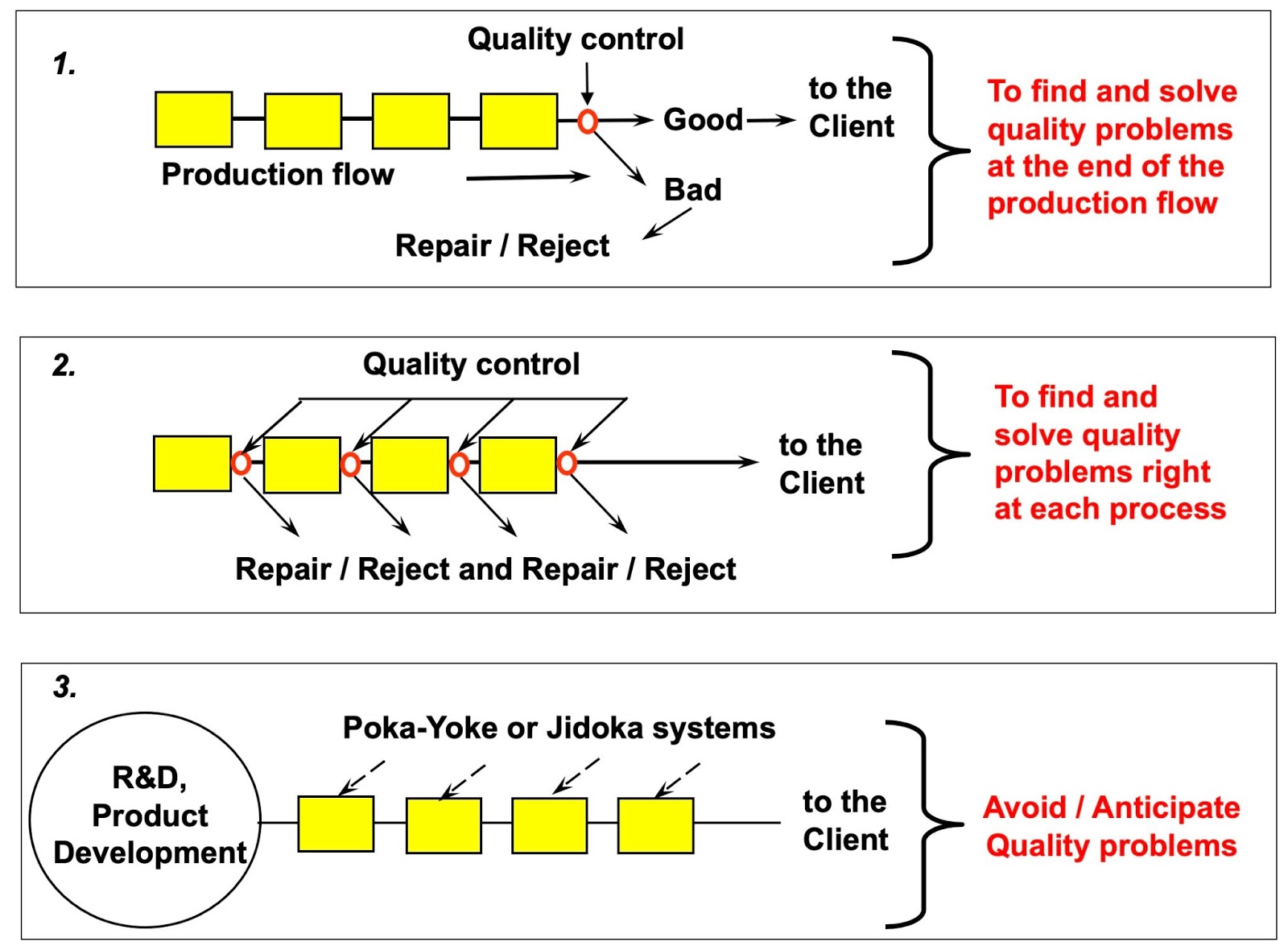

UPSTREAM MANAGEMENT

Problems must be managed as much as possible upstream from where we found them.

The further upstream we intercept the problems, the lower the cost of remedying them. For example, let's say we have complaints from the customer's point of sale. The cost of remedying poor quality, in this case is as high as possible since in addition to the damage to the image on the market, there are all the costs of transport from the point of sale, withdrawal from the supply chain, warehouse reconditioning, reconditioning, etc.

How much cheaper would it not have been if we had been able to adopt the kaizen process and adopt this concept to anticipate and solve the problem in the product design phase?

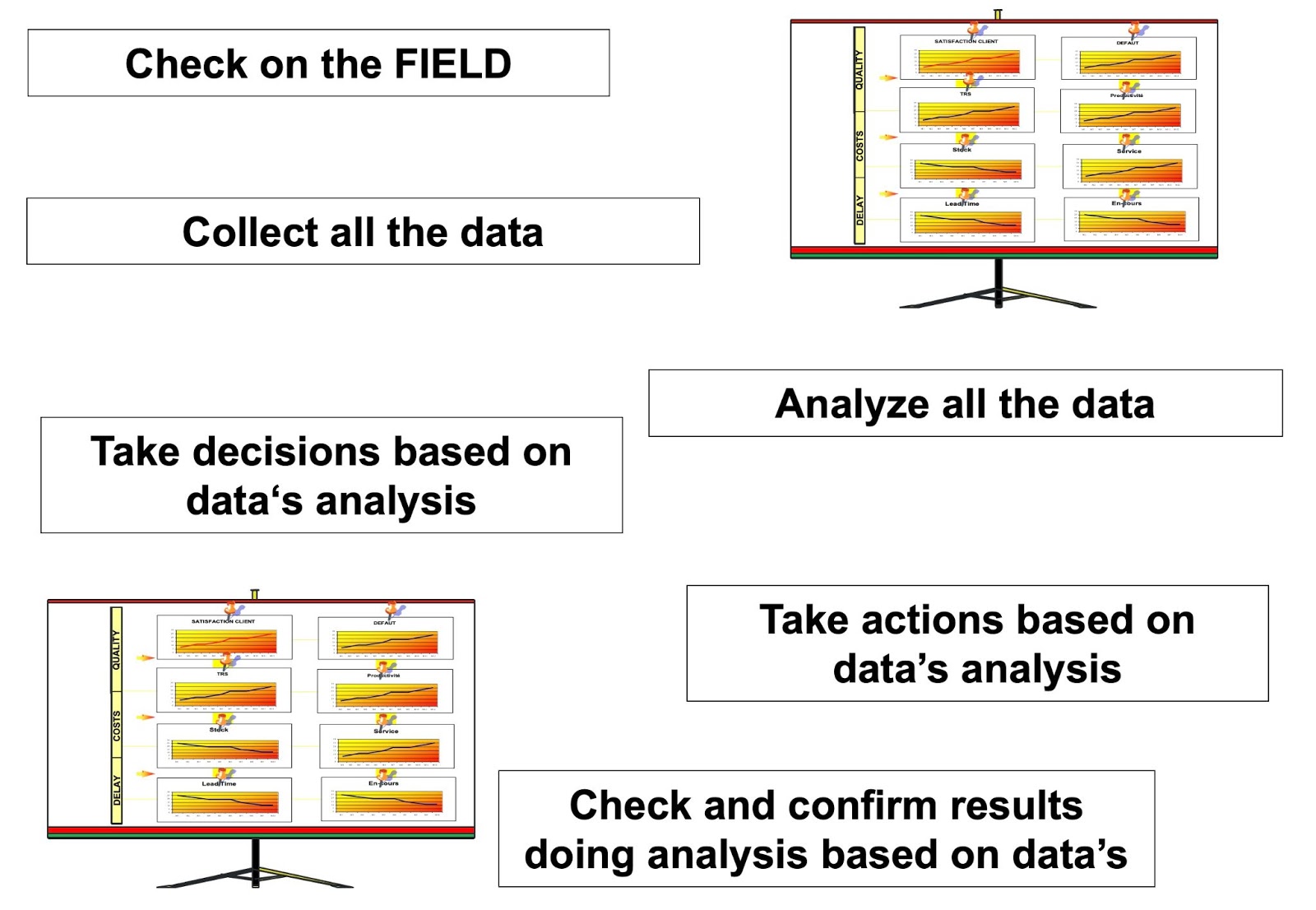

SPEAKING WITH DATA

This Kaizen process concept requires that the execution of one's work is always based on data. If the work is not based on data, it automatically becomes based on opinion and this makes it difficult to share a problem on objective basis.

If you do not have reliable data on which to base the activities, you must stop before acting and launch the data collections you need.

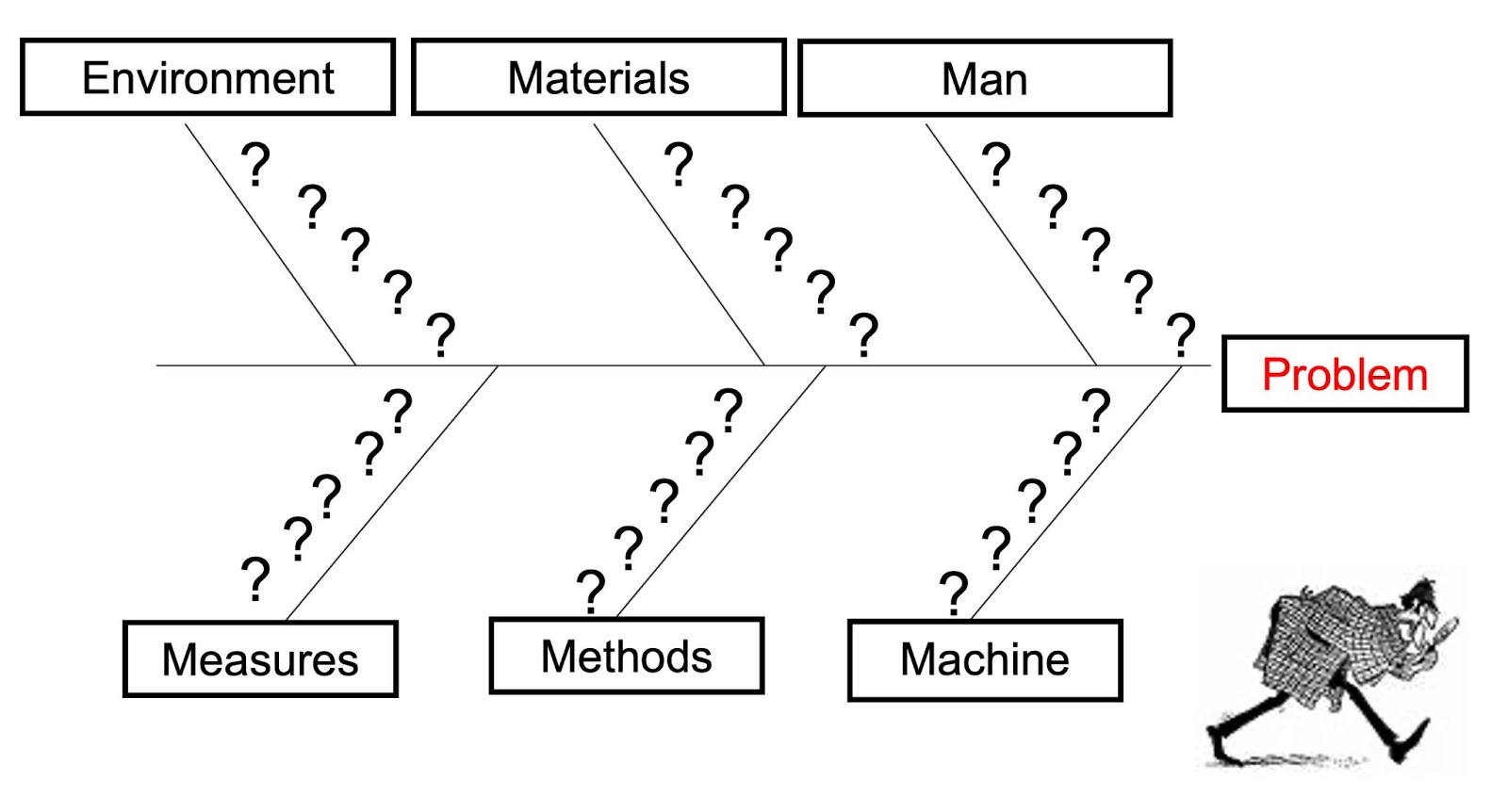

VARIABILITY CONTROL

The control of the variability that enters a system is a fundamental point to obtain stable processes to produce efficiently and with the right quality required by the customer.

In any production system there are always many factors at play that can vary and consequently that can cause the performance of business processes to vary. Too much out-of-control variability puts any company in crisis.

To keep variability under control it is necessary to establish solid operational standards which must in any case be continually challenged by a Kaizen approach.

To make sure we set standards for each variable in play we can use the Ishikawa diagram (pictured).

THE KAIZEN PROCESS IS MADE UP OF 3 PRINCIPLES AND 7 NON-NEGOTIABLE CONCEPTS.

As already mentioned above, the principles and concepts of this philosophy are the indispensable conditions for the formation of a true Kaizen corporate culture.

When they constitute the modus operandi of the company; all collaborators who will use them as a decision filter will be sure to always take the rights and winning decisions.