We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

Team building

In the company, it is possible to see the force of resistance to change at work just as soon as new ideas which in fact question the entire hierarchy, are introduced.

The resistance to change is much stronger the closer you get to the vertex of the company pyramid.

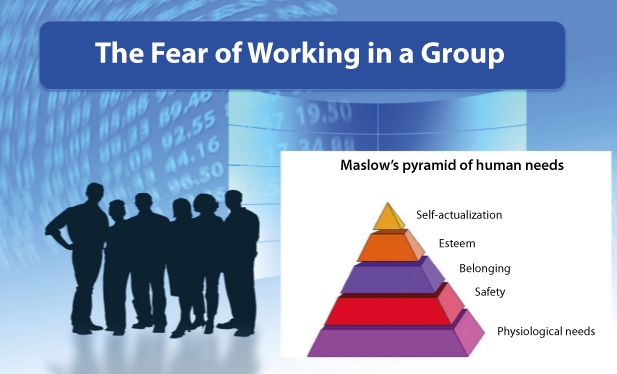

Lean Manufacturing and the Kaizen philosophy of continuous improvement are based on work groups. It is not possible to implement WCM or TPM if we are unable to manage and promote teamwork.

What are the base conditions that a good Kaizen coach must create so that the group performs very well?

If we study the various graphic representations of the Toyota Production System, Just in Time, TPM and WCM, it is possible to notice that in these models there is always the recall at the involvement of all the company people.

The neverending improving work is done to get rid from wastes and to improve the value aggregation in work activities and this is the daily focus of a company that follow the Lean Production paradigm. This work can be done efficiently and with a R.O.I. only if the problem solvings workshops are always done with a 360° vision and opennes attitude about the analyzed problems; this is the basic attitude that is required and it is necessary to develop in a lean team work.

It is proved that putting change into effect means that the person or the team who must operate the change is going from the comfort zone to the performance zone.

As already explained widely in the preview of the book “Team Building for Lean Production” (see banner here below), the comfort zone can be defined as the combination of ways of thinking and habits that a person or a work team has no interest in changing.

Even if they do not say so openly, many “old style” managers think that forming independent work groups is only a waste of time.

They believe that most of the time, the work meetings of a team are: unproductive, too long and lead to insufficient results.

The reason for this is that, deep down, they definitely know how things must be done and what the best solutions for the company are.