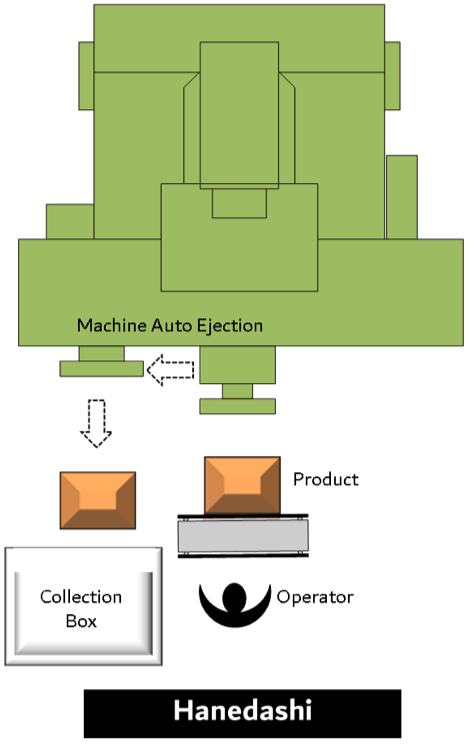

The word Hanedashi literally means ‘Automatic Ejection’ or in details understood as « automatic ejection of a piece after its transformation cycle »

Hanedashi principle is used as the means for automatized unloading of work item from one process or operation, providing the correct state for the next item to be loaded. A key component of Hanedashi device (machine operating on Hanedashi principle) is Chaku-Chaku lines. When couple of Hanedashi principle equipped machines are placed in sequence, they form a chaku-chaku line which means “load-load”. Because of the auto discharge of the part, the operator can run several machines with little waste.

As a normal practice the operator would have to put down the new part that had to be carried to the machine, pull out the complete part and put it down. Then, the operator takes the new part, loads it, and then again picks up a new part once it’s completed.

When a machine works on the Hanedashi principle, the operator inserts the part into it manually. The part then passes through the processes in an automatic sequence. Afterwards, it is automatically ejected. The operator then passes it to the next machine or to the next processor. While the part it has ejected is being passed on to the next process, the machine automatically returns to its initial position for the new piece can be inserted. The operator gets an empty machine which leads to immediate loading of the new part, pick up the completed part. This completes the cycle of the operation. Thus, this kind of device reduces waste when an operator approaches a machine to load the next part.

Benefits of Hanedashi

- Operator safety: As it automatically removes any chance mistake during manual loading and unloading.

- The benefits of a production facility built on the Hanedashi principle are that the operator would need less time to process an individual part, which means that throughput can be increased.

- Reduction in handling work makes the process more stable.

- Reduce Labor/Effort of work increasing productivity.