We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

Are you a professional lean trainer ? Do you want to receive new business opportunities ? Join for FREE our global network Register Here

OEE Overall Equipment Effectiveness - Lean Training

Quantify and reduce the losses of yours production lines

OEE Overall Equipment Effectiveness is the most important KPI to consider when managing production lines; unfortunately, it is also one of the most misconceived and distorted KPIs. This OEE training did justice to this KPI concept through an accurate, in-depth explanation and an in-depth analysis of your company's measurement of production line effectiveness.

Suppose your company is on the way to defining or improving the OEE application. In that case, this OEE training is ideal for all the managers involved to have a non-biased occasion to discuss and decide what to do with production line performance measurements.

In this OEE training, we will show you many examples of the OEE application for our clients in other companies.

Objectives

- Learn the principles of the OEE (Overall Efficiency Equipment).

- Master the OEE (Overall Efficiency Equipment) application in the management of the company (planning, cost, effectiveness, objective, Start-up curve for a new product, …)

- Apply the OEE knowledge to your actuals production lines performances meauserements.

- Utilize the knowledge acquired through the OEE to improve production lines performances.

- Recognize the OEE (Overall Efficiency Equipment) evaluation traps.

- Improve the OEE (Overall Efficiency Equipment) adoption by middle managers and operators

What is this training about

This OEE training is about utilizing this KPI concept for your production line effectiveness measurements and improvements.

After learning the concept in depth during this OEE training, we will run multiple practical examples using your company data.

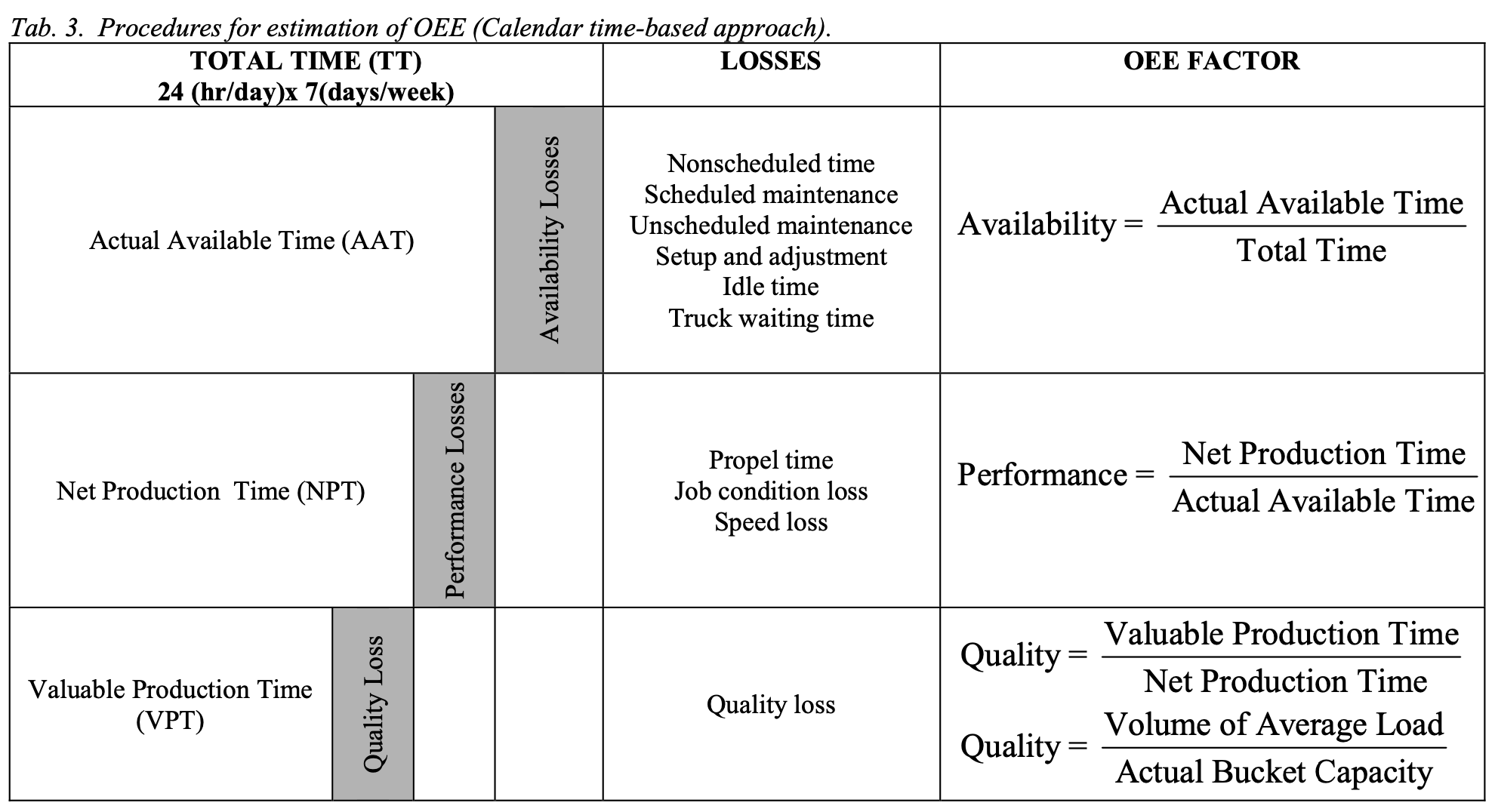

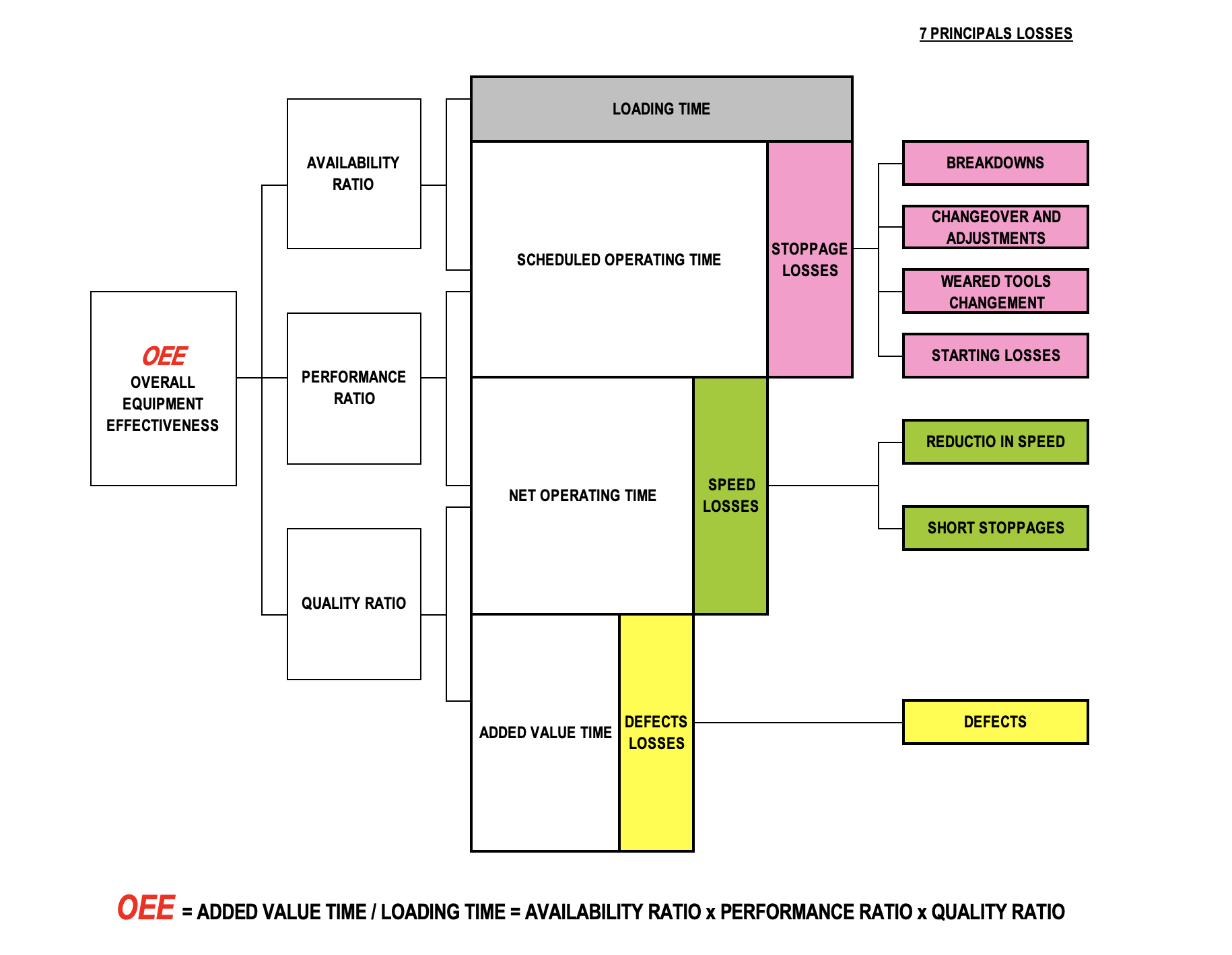

Through these examples, you will understand the nitty gritty of the 3 OEE factors: availability, performance, and quality.

When correctly opened, each of these factors represents a window of opportunities to improve the factor continuously.

It will be possible to discover solutions and to make an action plan to improve:

- Availability

- Performance

- Quality

This OEE training is not a training; it is a workshop where you can learn by doing.

Why your company have to do this training

Your company has to run this OEE training because there is no better way than OEE to control your plant's performance than knowing what OEE is and acting to improve it.

In this OEE training (workshop), we will apply the OEE and TPM theory directly to your production lines.

What you will be able to do after the Online

After this OEE training, the participants will be able to:

- Calculate the OEE of their production lines.

- Formulate an action plan to improve the production lines' performance.

- Decide which improvement action has the highest priority.

- Build their graphic tool to calculate the OEE.

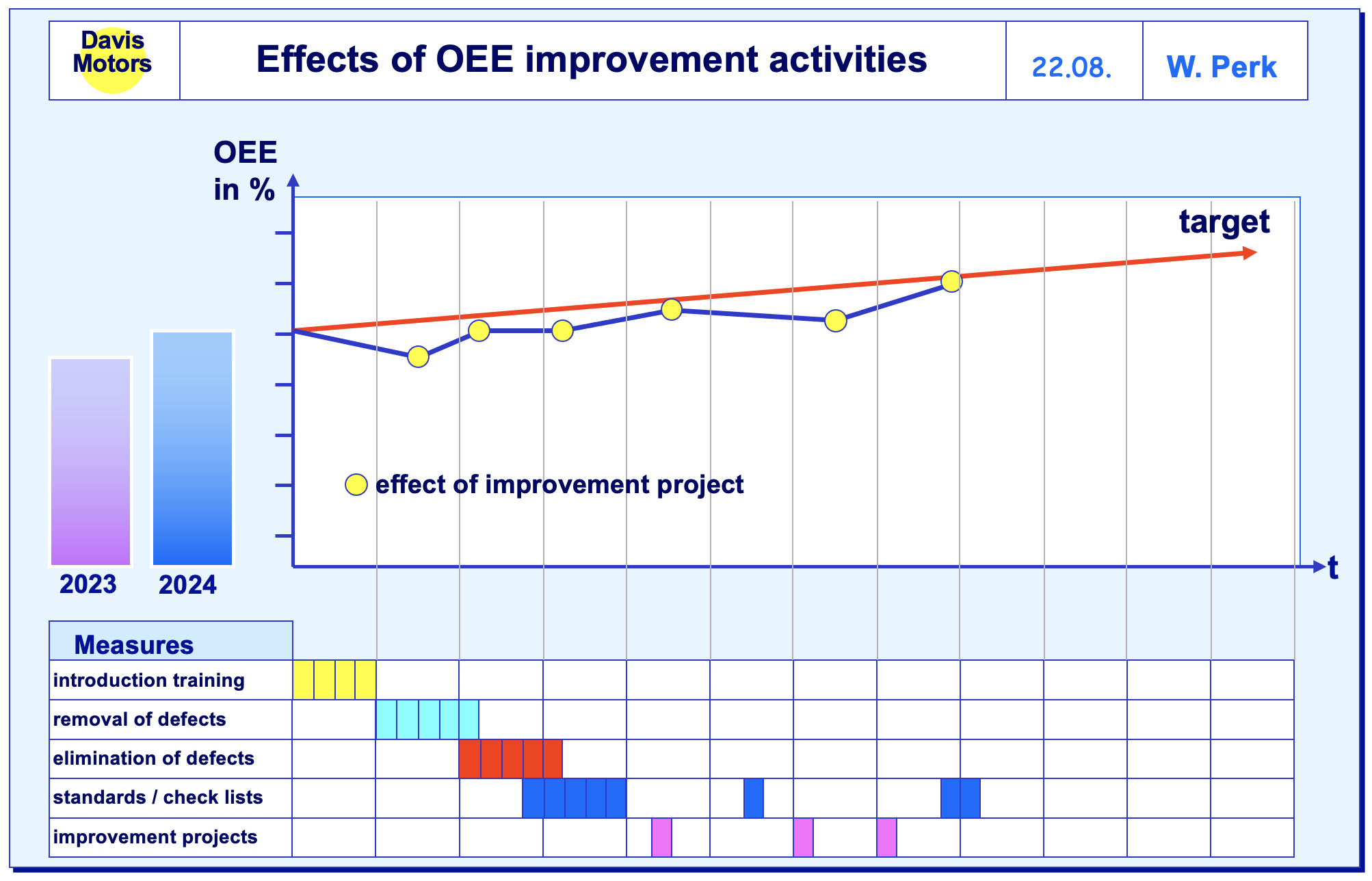

- Regularly track the OEE.

- Communicate and teach to their collaborators what the OEE is.

- Clearly explain the factors that affect, in positive or negative terms, the production lines' performances.

Participants

Date & Duration

Locations & Fees

Information request

Detailed training program

Day 1:

- Introduction

- Relation between the continuous improvement instruments and OEE (Overall Efficiency Equipment)

- The 16 major losses

- Definition and calculation method of 2 types of OEE -Overall Yield Rate (Machine and Man)

- Calculation exercise

- Application exercise and analysis of the result

- Testing

- Application of OEE (Overall Yield Rate) in the management of the company

Day 2:

- Recognize the evaluation traps of OEE (Overall Efficiency Equipment)

- Perennate the management system of the verification framework

- Actual cases of management application through OEE (Overall Efficiency Equipment)

- The approach of different improvement methods (Micro-arrest, …)

- Summary

- Assimilation Quiz

- Session closure

Those who have participated in this module have also participated in:

Reviews by some of our participants

Gianluigi M, Production Director, THALES Belgique.

« What interested me the most? The attributed manpower time and the definition of OEE (Overall Efficiency Equipment)».

Ask to be guided on your training choice by an experienced consultant

We offer a 30-minute free call. Our support offer is real and our consultants will give their best so that the advice is of maximum use to you; it will be up to you and only to you to ask about any additional paid support; we will not ask for anything.

Guarantees:

- This consultation does not hide any attempt to sell.

- No attempt to sell will be made

- We will not use your data for commercial purposes

- All your information will remain confidential

This type of consultation is carried out via the internet and through the Zoom application.

To reserve your consultation fill out the form below, you will receive by email a response of acceptance and confirmation of the consultation session.

Mario Mason

Lean Senior Consultant

Please follow the instructions to schedule a time with me. It's quick and easy.

Thank you.

If you have any questions or uncertainties about this training, please submit them using this form.

We assure you that we will provide a response within 24 hours if your inquiry is submitted between Monday and Thursday.

The Kaizen Coach Team