We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

Are you a professional lean trainer ? Do you want to receive new business opportunities ? Join for FREE our global network Register Here

Total Productive Maintenance Strategy Training

How to Define the Strategy for the Maintenance Service

When a company experiences frequent breakdowns and costly downtime, it has surely not reached the highest levels of the Total Productive Maintenance (TPM) model. Instead, it is likely operating in the Corrective Maintenance mode, which is the least desirable and most expensive approach.

To overcome this situation, its management's highest levels should wholeheartedly adopt the methods and practices of the industry's best-in-class organization.

By embracing this proven methodology, (TPM) the company can transition from reactive to proactive maintenance, ultimately reducing downtime and associated costs.

Objectives

Learn how to continuously improve the Maintenance Service and transition it to the heights of the Total Productive Maintenance Service model:

- Detailed Presentation of All Steps to Achieve Professional Maintenance Level: Provide a thorough overview of the necessary steps and procedures required to elevate the maintenance service to a professional standard.

- Learn the Benchmark Criteria According to JIPM (Japan Institute of Plant Maintenance): Establish performance benchmarks and best practices for your plants based on the guidelines and standards set by the Japan Institute of Plant Maintenance.

- Teach how to audit the actual level of the maintenance service. Presentation and training for the auditing tools for the maintenance service.

- Show on the shop-floor how to audit the maintenance service, ensuring all team members are familiar with the audit system and its goals.

- Build a corporate common strategy for the maintenance service that fulfills the next exercise financial period.

- Offer guidance for autonomous maintenance practices, and decide a strategy to implement it.

- Decide what and how to stimulate improvements in the actual maintenance service.

- Decide which area and type of equipment need to be brought under special focus by the maintenance service.

What is this training about

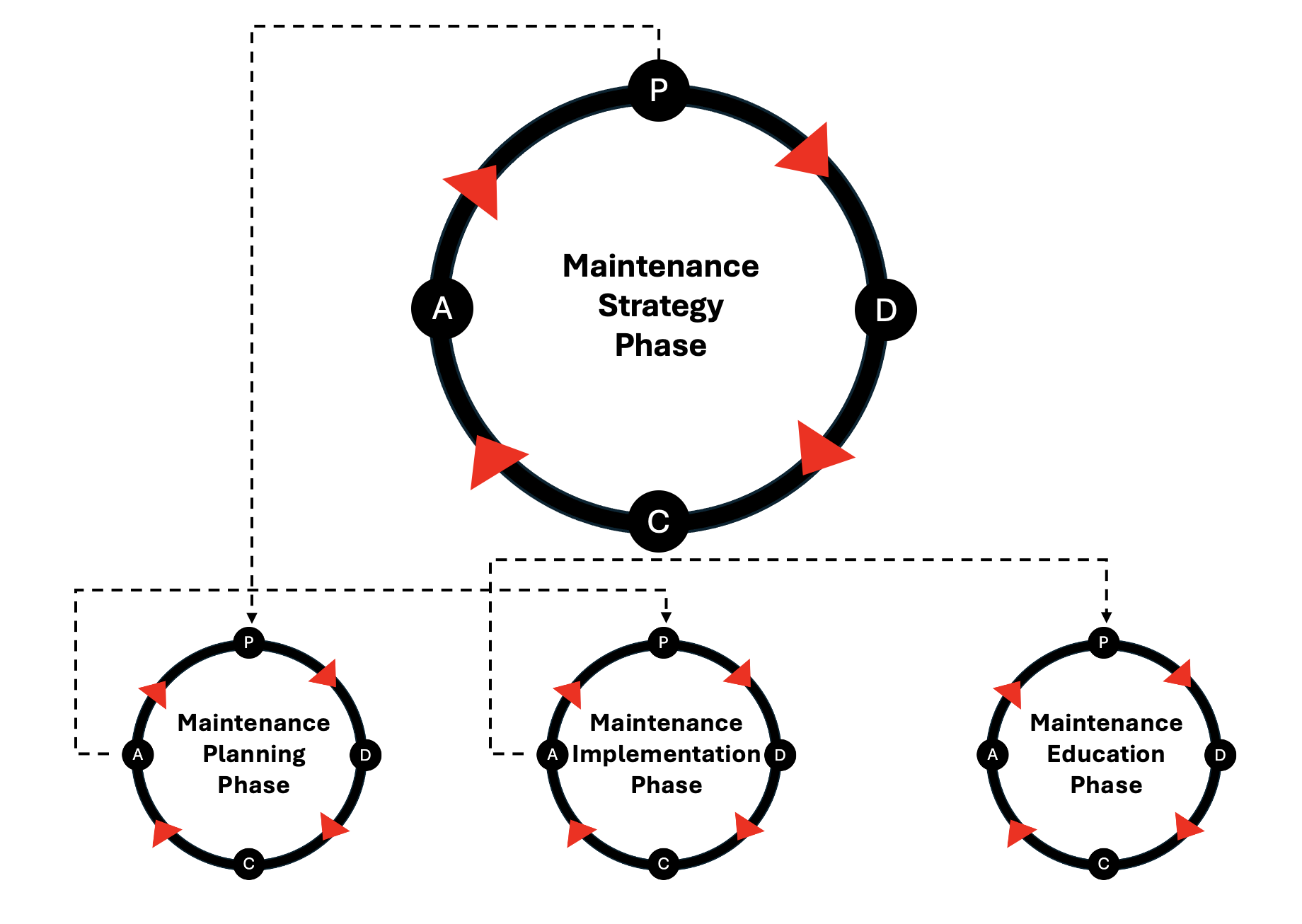

This training focuses on transitioning from Corrective Maintenance to Total Productive Maintenance.

It explains and outlines the strategy and action plan to realize this shift.

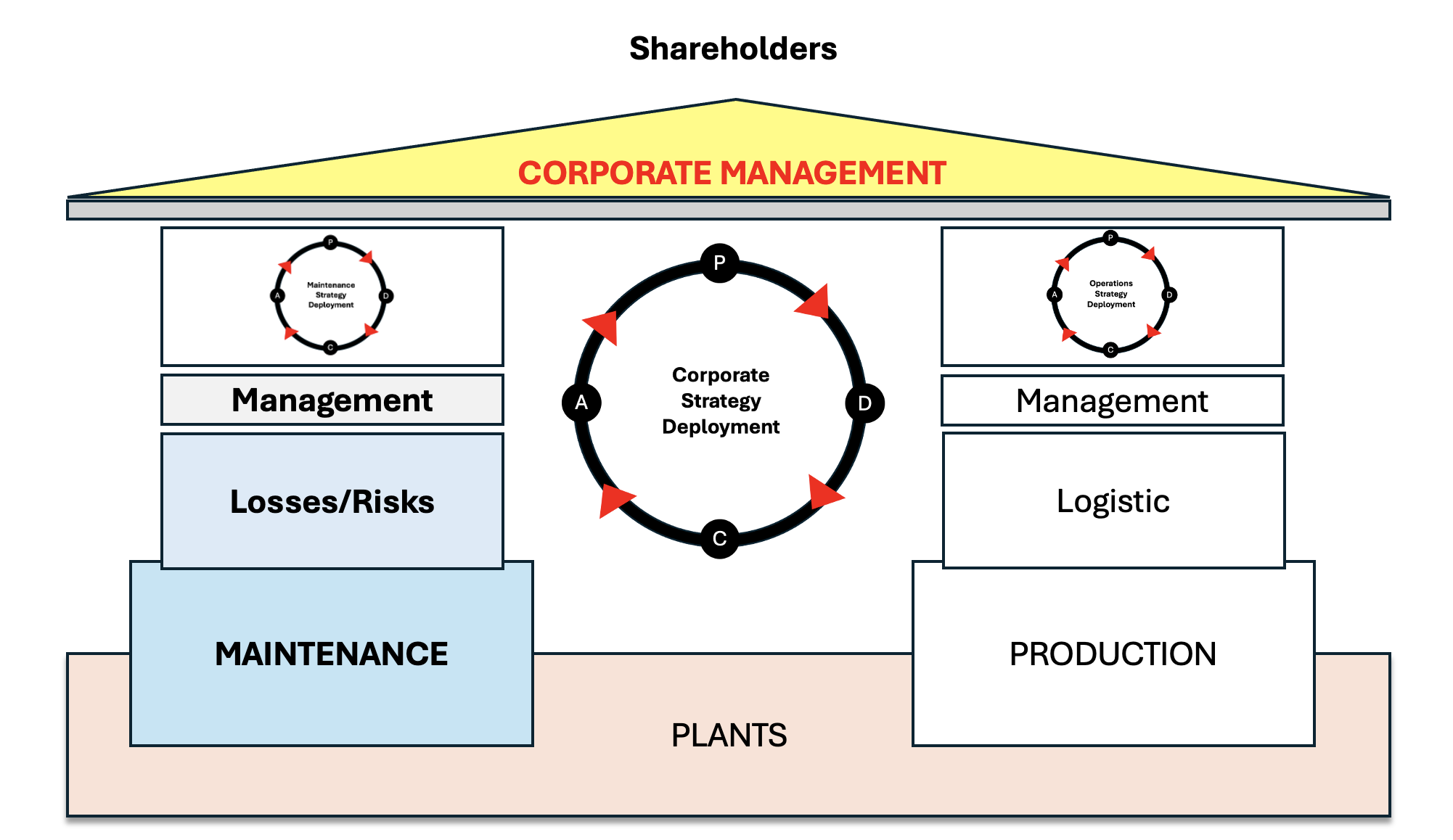

The function for total company optimization is nothing but corporate management. The will of corporate management is embodied as individual management tasks. Thus, implementing maintenance at the companywide level requires a framework of maintenance as corporate management. *Here, “management” is defined as “coordinated activities to direct and control tasks of an organization in order to attain its goal.

Why your company have to do this training

This training is necessary when the management team needs to develop or review the company's maintenance service strategy.

There are times in a company's life when revisiting the basics is essential, and structured training is the best way to refresh all managers' perspectives on implementing best-in-class reliability practices.

This training is not only theoretical but overall is very practical because it uses the company data and can be held in sight of:

- Next financial year exercise budget definition.

- Review of the maintenance service budget.

- Review of the maintenance performance KPIs.

- Crisis when it is really necessary to turn around performances and results.

What your collaborators will be able to do after this training

After the training, the management team will be able to:

- Redesign the maintenance service strategy, accordingly with the company goals and the Total Productive Maintenance model.

- Develop an action plan for the maintenance service that fulfills the company goals

- Allocate the required resources.

- Implement effectively the action plan.

- Monitor the strategy execution and adjust the direction if necessary.

(The points 1, 2 and 3 will be developed during the training)

Participants

Date & Duration

Locations & Fees

Information request

Detailed training program

Day 1:

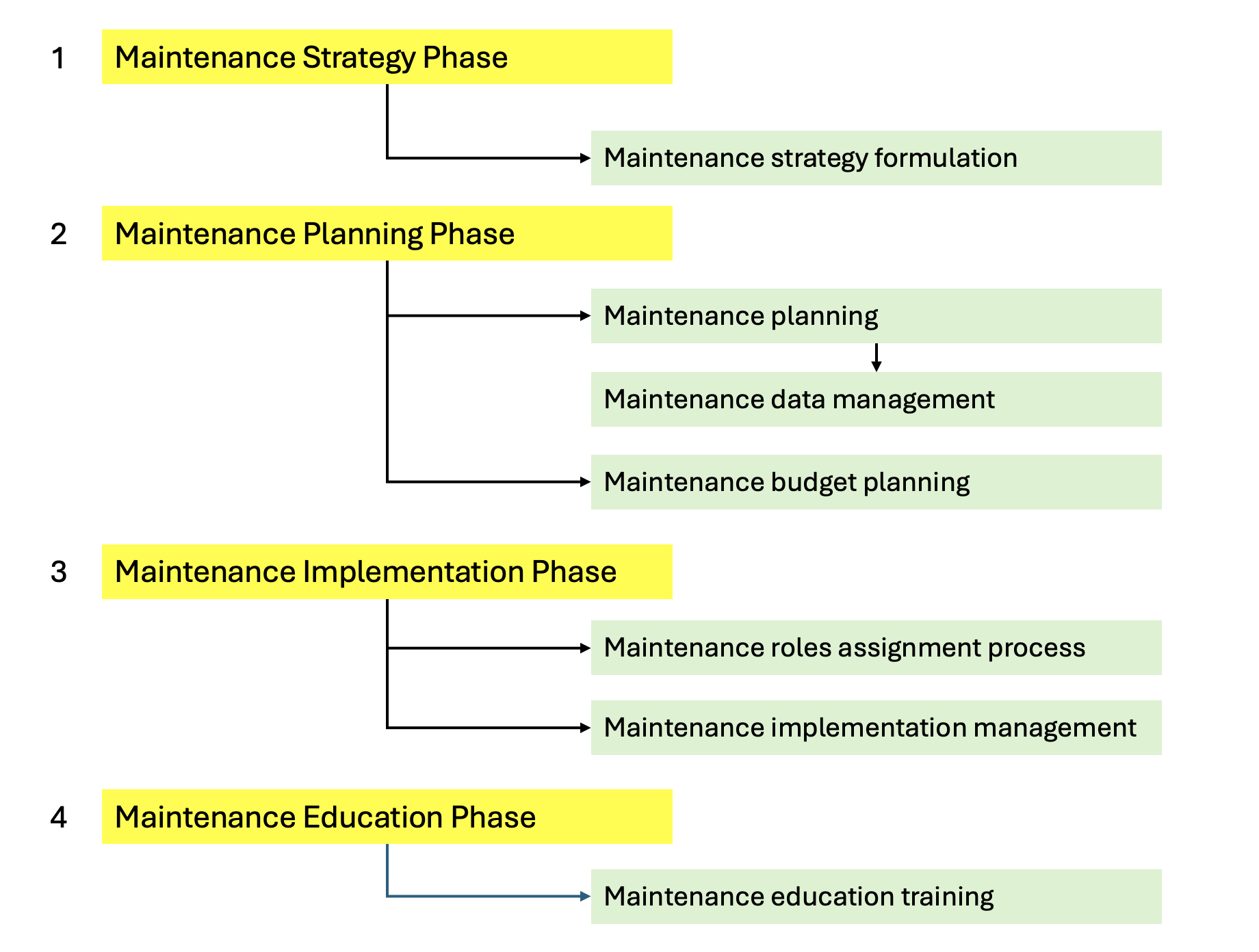

- Review of the Optimal Strategic Maintenance Management System.

- Link creation between Company Goals and Maintenance service.

- Review of Maintenance Audit report (completed prior to training).

Day 2:

- Development of the Maintenance Strategy.

- Plant visits to relevant areas concerning the Maintenance Strategy.

- Definition of Maintenance Key Performance Indicators (KPIs).

Ask to be guided on your training choice by an experienced consultant

We offer a 30-minute free call. Our support offer is real and our consultants will give their best so that the advice is of maximum use to you; it will be up to you and only to you to ask about any additional paid support; we will not ask for anything.

Guarantees:

- This consultation does not hide any attempt to sell.

- No attempt to sell will be made

- We will not use your data for commercial purposes

- All your information will remain confidential

This type of consultation is carried out via the internet and through the Zoom application.

To reserve your consultation fill out the form below, you will receive by email a response of acceptance and confirmation of the consultation session.

Mario Mason

Lean Senior Consultant

Please follow the instructions to schedule a time with me. It's quick and easy.

Thank you.

If you have any questions or uncertainties about this training, please submit them using this form.

We assure you that we will provide a response within 24 hours if your inquiry is submitted between Monday and Thursday.

The Kaizen Coach Team