We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

Are you a professional lean trainer ? Do you want to receive new business opportunities ? Join for FREE our global network Register Here

Autonomous Maintenance Training

Reduce losses with an autonomous maintenance training experience

Autonomous maintenance is a pillar of the Total Productive Maintenance (TPM) system, assembled in its philosophy from the Japan Institute of Planned Maintenance (JIPM).

The fact that it is a pillar means that it cannot be avoided in implementation; all other types of maintenance will be significantly more costly if autonomous maintenance is not implemented.

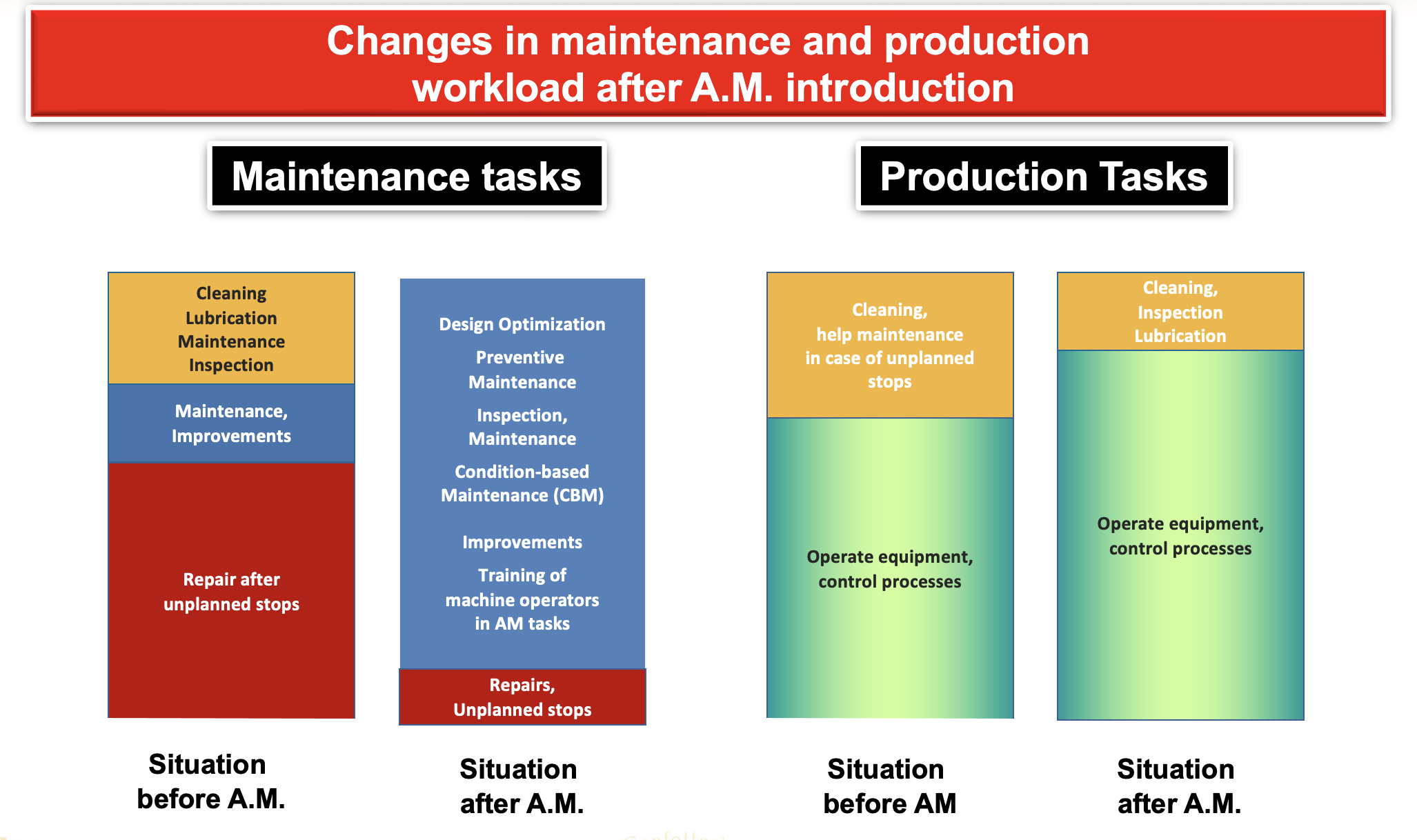

Apart from being part of the TPM model, autonomous maintenance should also be seen as the bridge between production and maintenance. If this bridge is not established through autonomous maintenance, both functions will significantly cost more, and the value created by the enterprise will be significantly diminished.

We will explain these reasons in depth during the autonomous maintenance training, but experienced professionals and knowledgeable managers already understand the importance of this approach.

Objectives

- To learn the role of Autonomous Maintenance in TPM.

- To learn the benefits of implementing Autonomous Maintenance.

- To experience Autonomous Maintenance on specific equipment.

- To learn the necessary organization to run an A.M. workshop.

- To know how to deploy Autonomous Maintenance in the rest of the plant.

What is this training about

In this training, participants will experience the preparation, intensive, and follow-up phases of a workshop designed to implement the autonomous maintenance methodology on equipment.

The equipment will be selected during the preparation phase based on its loss performance and strategic plant reasons.

During the workshop preparation phase, the principles of autonomous maintenance will be theoretically explained (with visits to the shopfloor where the chosen equipment is installed) to an autonomous maintenance facilitator.

In the intensive phase of the workshop, participants will work intensely on the equipment to meet the methodology's requirements.

In the follow-up phase, participants will observe the results of the autonomous maintenance application and will work on refining their efforts from the intensive phase.

Why your company have to do this training

In the process industry, value is primarily generated by equipment, and as a result, they must never stop, produce at the forecasted performance level, and maintain the highest quality level.

To achieve these conditions at their maximum level, maintenance must perform exceptionally well. This can only be accomplished if the maintenance operates at the lowest possible level of breakdown maintenance.

Autonomous maintenance is the master methodology for preventing breakdowns. Since autonomous maintenance is performed by the production crew, it can prevent breakdowns before they occur through inspection routines and first-level basic maintenance interventions. This allows "professional maintenance technicians" to focus on studying and executing planned maintenance, preventive maintenance, and predictive maintenance.

Autonomous maintenance frees professional maintenance technicians from performing low-cost basic tasks.

A plant that does not implement autonomous maintenance will incur higher maintenance costs and suffer more significant losses.

What your collaborators will be able to do after this training

After this initial autonomous maintenance training, your facilitator will be able to:

- Choose the equipment in accordance with TPM principles

- Evaluate the workload for the chosen equipment for the different steps of the A.M.

- Prepare the necessary information for the training

- Choose the right participants for the team

- Run the training days, knowing exactly what to do at every moment

- Run the training phases, knowing the targets for each phase

- Follow up on the action plan after the intensive training days

- Communicate effectively to the company/plant stakeholders about autonomous maintenance.

Participants

Date & Duration

Locations & Fees

Information request

Detailed training program

Preparation Day (with chosen facilitator)

- Equipment choice

- Visit the chosen equipment for a first evaluation

- Team participants

- Data gathering about the equipment and organization

- Training on training methodology (only facilitator)

- Training on autonomous maintenance methodology (only facilitator)

- Establish training day agendas

- Communication strategy for the training

Ask to be guided on your training choice by an experienced consultant

We offer a 30-minute free call. Our support offer is real and our consultants will give their best so that the advice is of maximum use to you; it will be up to you and only to you to ask about any additional paid support; we will not ask for anything.

Guarantees:

- This consultation does not hide any attempt to sell.

- No attempt to sell will be made

- We will not use your data for commercial purposes

- All your information will remain confidential

This type of consultation is carried out via the internet and through the Zoom application.

To reserve your consultation fill out the form below, you will receive by email a response of acceptance and confirmation of the consultation session.

Mario Mason

Lean Senior Consultant

Please follow the instructions to schedule a time with me. It's quick and easy.

Thank you.

If you have any questions or uncertainties about this training, please submit them using this form.

We assure you that we will provide a response within 24 hours if your inquiry is submitted between Monday and Thursday.

The Kaizen Coach Team