We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

Are you a professional lean trainer ? Do you want to receive new business opportunities ? Join for FREE our global network Register Here

Lean Foundations and Principles

Learn the Lean Foundations and Principles, achieve our certifications.

Learning the Lean Foundations is a must for those who want always to choose the right action and action plan to improve company performance. Lean Foundations are made of some simple principles, concepts, and methodologies that, as always (for foundations), seem simple, and they are, but at the same time, they imply some deep meanings. These meanings have changed the industrial world in the last 50 years. Not knowing the lean foundations means not having a grid that permits one to read any industrial environment correctly.

Objectives

- Discover the lean principles and concepts that constitute the Lean foundations.

- Understand how to implement Lean foundations in a lean implementation project for your company.

- Discover the primary methodologies of Lean Manufacturing and Lean Services.

- Dynamize your company' Gemba.

- Implement the first Lean workshops

- Define the Lean training plan about lean principles and lean foundations.

- Understand how to build R.O.I. with your Lean project implementation.

What is this training about

This Lean Foundations training is about understanding the three principles and seven concepts of lean manufacturing at the deepest level. Furthermore, you will learn some basic methodologies that are outspring from the lean foundations at a level of comprehension that will allow you to understand how to utilize the methodologies in your company and for your own lean implementation project.

Why your company have to do this training

Without a grasp of lean foundations and principles, your collaborators will never be independent in finding new solutions for your specific problems.

What your collaborators will be able to do after this training

After this training in lean foundations and principles, your collaborators will be able to:

- Distinguish value-added activities from NON-value added

- Be able to prioritize action improvements according to lean foundations and principles.

- Redesign action plans accordingly with lean foundations and principles.

- Communicate to their collaborators the meanings of lean foundations and principles.

- To organize a lean implementation project.

Participants

Date & Duration

Locations & Fees

Information request

Detailed training program

Day 1:

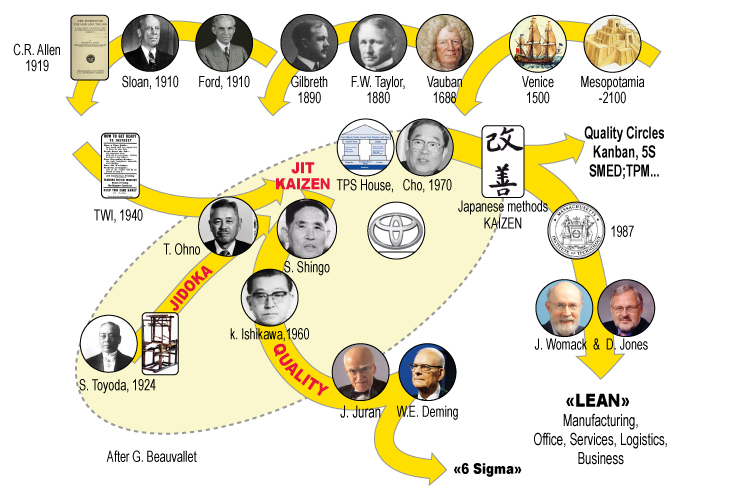

- Lean presentation and history

- Principles and concepts

- Lead Time

- Value added

- Gemba

- Muda

- Lean program implementation

- The traps to avoid

- The keys to success

- Increase the value of the profits

- Auto-evaluation of Lean

Day 2:

- Presentation of the various Lean methodologies:

- Value Stream Mapping (VSM)

- Just In Time (JAT)

- Total Productive Maintenance (TPM)

- 5S

- SMED

- Lean Product & Process Design

- Gemba Kanri

- Lean Ergo

- Lean Office and Services

- Lean workshops

- Analysis of practical cases

- Individual projects and exchanges

- Assimilation Quiz

- Issuance of certificates

- Session closure

Those who have participated in this module have also participated in:

5S and Visual Management

Value Stream Mapping

Structural Methods of Problem Solving

The bases of Just In Time (JIT)

Total Productive Maintenance Basics

Reviews by some of our participants

Laurent G., Quality Manager, LVMH

« A vision, a culture, a motivation… »

Thierry C., Financial Director, ABTEY Chocolate shop

“This training helped me to understand Lean better and answered my question:

Why implement Lean in my company?”

Mr B., Intern, Christian Dior Couture

« This training gives you the desire to act.»

Mr Stéphane G., Team Leader, Essilor

« Finally, a training appropriate for our reality, I recommend it to all operators and people curious about Lean.»

Ghyslaine C., Responsabile Supply Chain, HAULOTTE

« The principles of Lean, the illustration through concrete examples, supported by application exercises – A more global vision of Lean and a better comprehension of the connection of the instruments in relation with each other. »

Ask to be guided on your training choice by an experienced consultant

We offer a 30-minute free call. Our support offer is real and our consultants will give their best so that the advice is of maximum use to you; it will be up to you and only to you to ask about any additional paid support; we will not ask for anything.

Guarantees:

- This consultation does not hide any attempt to sell.

- No attempt to sell will be made

- We will not use your data for commercial purposes

- All your information will remain confidential

This type of consultation is carried out via the internet and through the Zoom application.

To reserve your consultation fill out the form below, you will receive by email a response of acceptance and confirmation of the consultation session.

Mario Mason

Lean Senior Consultant

Please follow the instructions to schedule a time with me. It's quick and easy.

Thank you.

If you have any questions or uncertainties about this training, please submit them using this form.

We assure you that we will provide a response within 24 hours if your inquiry is submitted between Monday and Thursday.

The Kaizen Coach Team