We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

Are you a professional lean trainer ? Do you want to receive new business opportunities ? Join for FREE our global network Register Here

Maintenance Optimization Training

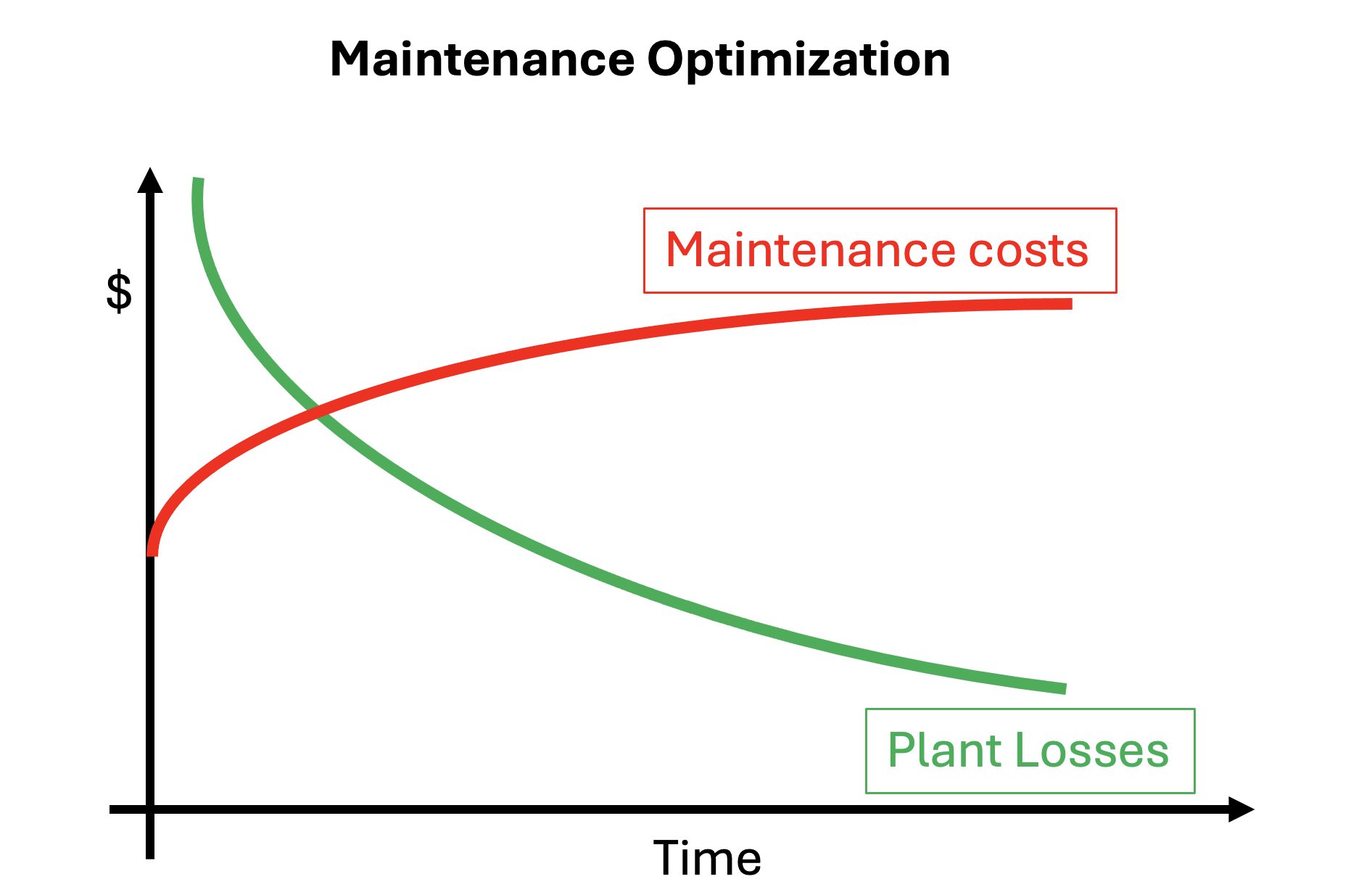

Learn how to optimize maintenance for losses and costs reduction.

In the process industry, value is created through well-functioning plants and equipment. As a result, the maintenance department, which is in charge of equipment effectiveness, is often under stress to perform well while keeping costs low.

Maintenance optimization is a crucial factor in maintaining business profitability. By reducing losses through Total Productive Maintenance (TPM) continuous improvement and refining the maintenance organization, companies can significantly enhance their profits.

However, maintenance optimization must be aligned with TPM principles. Otherwise, it could lead to increased breakdowns and decreased performance.

This training is not just theoretical; it is a hands-on workshop where all stakeholders will actively engage in a real-time maintenance optimization process.

Objectives

- Create awareness about the need of an effective relationship between the maintenance the production services.

- Optimize Autonomous Maintenance

- Optimize Planned Maintenance

- Optimize Predictive Maintenance

- Optimize Maintenance Costs

- Optimize Maintenance Competences

What is this training about

This maintenance optimization workshop aims to enhance all areas of interest in maintenance, from autonomous maintenance to predictive maintenance.

The optimization of autonomous maintenance will be achieved by analyzing the number of hours saved in corrective maintenance. Based on this analysis, we will improve all relevant standards in accordance with TPM methodologies.

Planned maintenance optimization will be carried out by examining various KPIs, such as the number of equipment breakdowns and lost performance, as well as the time and resources required for planned maintenance execution.

Predictive maintenance optimization will be achieved by analyzing the progress in reducing equipment non-availability and other key factors identified by the TPM philosophy.

A special focus will be placed on the competence and skills matrix, identifying areas of risk and potential improvements.

Why your company have to do this training

If you believe your company needs to optimize maintenance, reduce losses, and achieve appropriate costs, this maintenance optimization workshop is certainly for you.

Engaging an external, experienced consultant can provide a fresh perspective and stimulate necessary changes that may be overlooked by your in-house team due to familiarity.

What your collaborators will be able to do after this training

After the maintenance optimization workshop/training, your maintenance dept. will be:

- More acquainted with the TPM methodologies.

- Conscious of the improvement possibilities.

- Motivate by the facts that will arise to implement the related action plan.

- Capable of running autonomously new optimization workshops in the future.

Participants

Date & Duration

Locations & Fees

Information request

Detailed training program

This is the first draft of activities that must be carried out in the first days of the maintenance optimization training/workshop.

- Auto-evaluate the current situation of the relationship between Maintenance and Production services

- Establish the challenges and indicators

- Establish the action plan for improving the Maintenance service

- Define the strategy for the next days of the maintenance optimization.

Topics developed

- Meetings between the Maintenance and the Production Service

- Activity reports for the Maintenance service

- Involvement of personnel for the equipment maintenance

- Programming of the production stops for Maintenance

- Technical report to resolve problems with production

Ask to be guided on your training choice by an experienced consultant

We offer a 30-minute free call. Our support offer is real and our consultants will give their best so that the advice is of maximum use to you; it will be up to you and only to you to ask about any additional paid support; we will not ask for anything.

Guarantees:

- This consultation does not hide any attempt to sell.

- No attempt to sell will be made

- We will not use your data for commercial purposes

- All your information will remain confidential

This type of consultation is carried out via the internet and through the Zoom application.

To reserve your consultation fill out the form below, you will receive by email a response of acceptance and confirmation of the consultation session.

Mario Mason

Lean Senior Consultant

Please follow the instructions to schedule a time with me. It's quick and easy.

Thank you.

If you have any questions or uncertainties about this training, please submit them using this form.

We assure you that we will provide a response within 24 hours if your inquiry is submitted between Monday and Thursday.

The Kaizen Coach Team