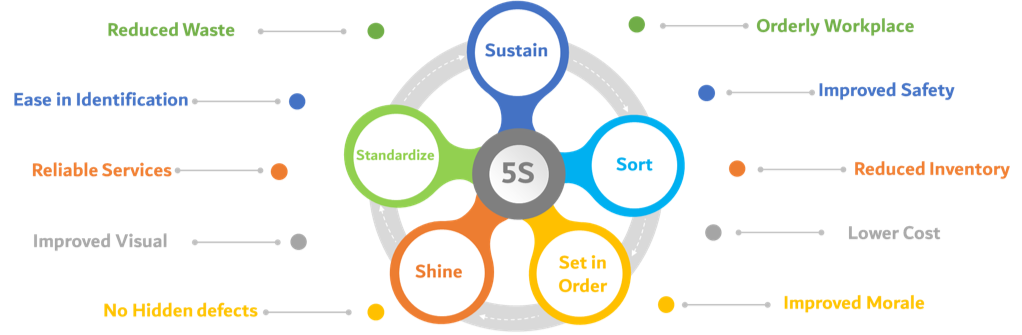

The 5S method is a Lean tool. It refers to Japanese terms: Seiri (整理), Seiton (整頓), Seisō (清掃), Seiketsu (清潔), and Shitsuke (躾).

This method is utilized to build an organized workplace with total and easy access to the workplace and full visibility of the necessary equipment, tools, environment, and services.

5S must be done in the exact sequence and each S is explained as follow:

- Seiri: Sort, eliminate, or reduce the useless.

In the workplace must be present only what is needed, only in the amounts needed, and only when it is needed. Thus, it means that is necessary to remove all unnecessary items that are not needed for the current operations and that do not add value. In this sorting phase, Red Tags are commonly used to identify the items that must be removed or need evaluation time to be removed. - Seiton: Set In order, organize.

It means organizing the workplace and the needed items. Each item should be easy to find, use, and return. One of the goals to achieve in this phase is commonly described as a place for everything, and everything in its place. This is one of the most important phases of the 5S methodology and if it is not done properly the final organizational result may not last. In this phase, it is suggested to organize the workplace following the principle to reduce or eliminate the 7 wastes we can find. - Seiso: Shine, cleaning thoroughly with the goal of determining anomalies.

It emphasizes cleanliness by removal of dirt, grime, scrap, and dust from the workplace. It involves the regular cleaning of every part of the workplace. Thus, cleanliness here means identifying and removing the cause of dirt and contamination. In this phase, it is necessary also to set up the necessary organization in terms of cleaning standard procedures, tools, and emplacement for stocking cleaning types of equipment and materials. - Siketsu: Standardize; the workplace organization becomes self-explained, evident, and visible (equipment, instruments, areas)

Standardization is establishing procedures and schedules in visual and written format to ensure the repetition of the first three ‘S’ practices under controlled conditions. What is to be done, and where and by whom that an organization can incorporate into the work system. This paves the way for long-term change. - Shitsuke: Sustain- Self Discipline to maintain the level.

It is defined as making a habit of maintaining established workplace standards. Its purpose is to make employees habitual to following the first three ‘S’ practices as per the standards. The idea is to continue the commitment. This phase is carried out through standard audits that will evidence discrepancies between what was established in the previous S and what is found during the audits.

Benefits of 5S:

- Provides opportunities for the employee to give creative inputs about the organization of the workplace and how it should be done.

- Creates a work environment in which spaces, energy, time, and other resources can be managed and used more productively.

- Makes the workplace more pleasant to work in.

- Removes the obstacles and frustrations caused due to disorganization in the workplace.

- Helps to understand what is expected to be done, and when and where it is expected to be done.

- Communication is improved for everyone because of 5S.

- Product quality is improved.

- Productivity is improved.

- Workplace safety is maximized.