AMDEC or Analysis of failure modes, their effects and their criticality is the English translation of the FMECA (Failure Modes, Effects and Criticality Analysis). It is the French equivalent of the original FMECA method.

AMDEC can be viewed as FMECA extends FMEA by including a criticality analysis, which is used to chart the probability.

It can be described as a method of qualitative and quantitative analysis of the probability of failure modes against the severity of their consequences. This tool is used in the quality process and in operational safety. This method is used to take corrective or preventive actions against product and process failures. It studies the feasibility of the specifications of the customer and legislative and regulatory requirements.

AMDEC analyses all the foreseeable failures, their causes, and their effects on final output desired by the customer.

Understanding the terms associated with AMDEC:

- The failure mode: This mode helps to search for failures in which the system can stop working, deviate from product specification, etc. It is expressed in physical terms.

- The cause of the failure: It is the anomaly that could lead to the failure.

- The effect of the failure: These are the consequences suffered due to the failure.

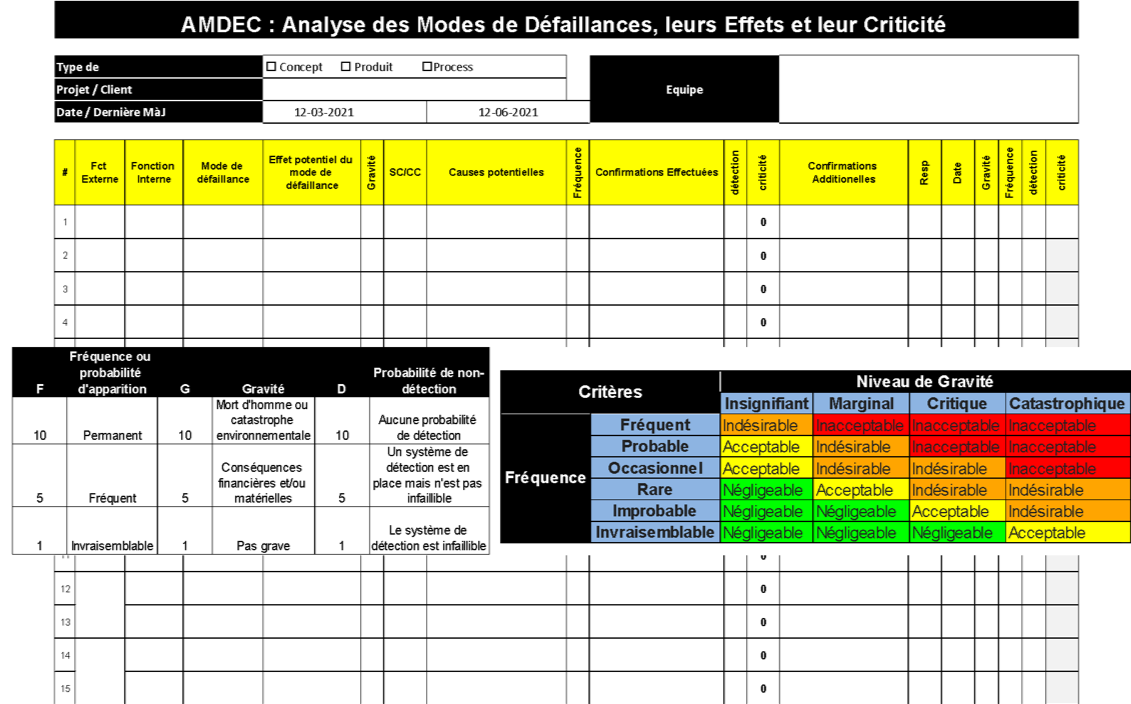

- Criticality: this factor determines the acceptability of a situation by combination of several other factors. Once the frequency, severity and detection organization can calculate the criticality score. The higher the criticality score, the greater the failure.

AMDEC is a very interesting tool for operational safety, in case of two failures occur at the same time on two subsystems, what will be the effect on the whole system? In such case, additional studies required, by fault trees or reliability block diagrams.

Criticality = Frequency × Severity × Detection

- Severity: or Gravity “What is the severity of Defect?”

- Frequency: or probability of occurrence “In What Frequency the defect occurs?”

- Detection: or Probability of non-detection “What is the likelihood of detection?”

The team then needs to prioritize the criticality of each failure mode and make action plan accordingly.

AMDEC Format consist of following columns:

- Component Or Sub-Assembly,

- Potential Failure Modes,

- Possible Causes of Each Failure Mode,

- Effects Of Each Failure Mode on The System,

- Frequency Index,

- Severity Index,

- Detectability Index,

- Current Criticality,

- Recommended Actions

- Responsibility

- Target Date

- Frequency Index after,

- Severity Index after,

- Detectability Index after,

- Result Criticality,