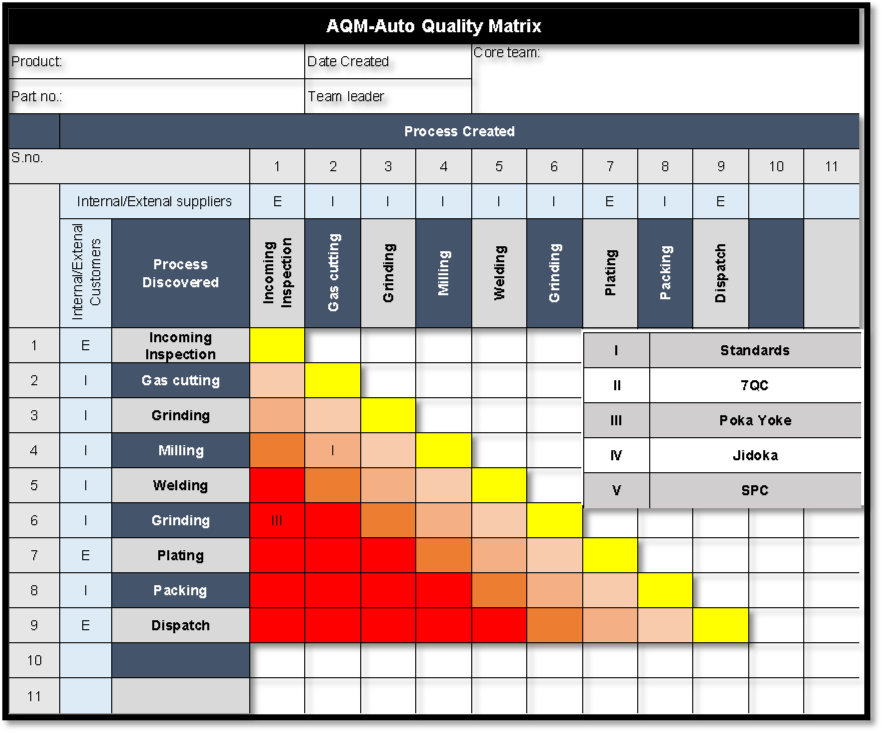

Auto-Quality Matrix is a technique to pinpoint where the defect is created and detected in the process of manufacturing.

Auto quality matrix works as Quality instrument on the field with the following objectives:

- Making the line’s quality level visual, workstation to workstation.

- Establish the relations between the identifying defect’s location and the original location.

- Allow for the management of the defects rate directly on the Gemba.

The implementation method for Auto quality matrix:

- Identify a line or a product based on its criticality.

- Open a "Training workshop" and motivating people to use this tool,

- Prepare a board with Auto quality matrix chart,

- Mark the processes in vertical and horizontal column(s),

- Plot to identify the process,

- Prepare action plan based on impact level of matrix in the identified process,

- See the results if the defects decreased or eliminated or if the situation improves,

- Standardize the results,

- Start horizontal deployment of the actions on similar type of processes if applicable and

- Involve people from other areas or process owners to convince them the benefits of this tool.

Breaking into Customers and suppliers:

Auto quality matrix can be broken down into Internal-External Suppliers and internal external customers.

Internal-External customers: Internal customer can be specified as the next process in line within the organizations premise. Whereas external customer can be Outsourced job work, third party or end user which is outside Organization premises.

Internal-External Supplier: Internal Supplier can be specified as the previous process where semi-finished product is being received within the organizations premise. Whereas external supplier can be Outsourced job work, third party or external suppliers which is outside Organization premises.

Auto quality matrix not only shows the creation and detection of defect it also gives visual base to act on them. A Process Owner, using the auto quality matrix for each defect they encounter, will not only help to get more in-depth insights but also by forcing them to map or to model processes & value streams. Key point here is that when you mark a reject on the Auto Quality Matrix chart, you also place a defect tag on the product with a quantity and collect all the defects in one location. This allows the people to go back and see what kinds of defects are being produced and in which processes.