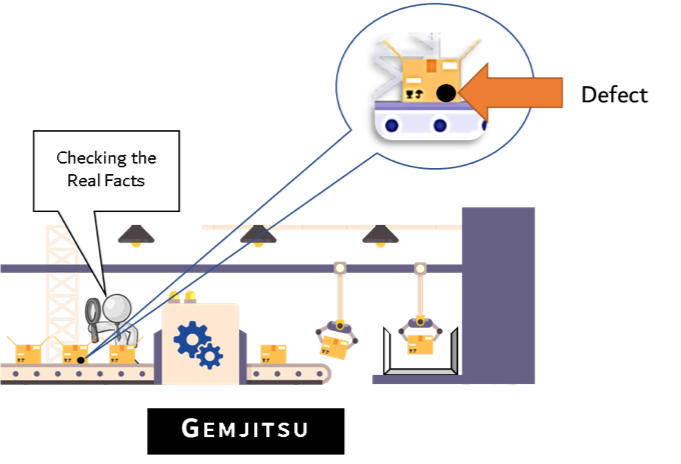

Gemjitsu or Genjitsu is Japanese word Literal translation “ the real facts” (現物); this means the invisible fact.

Gemjitsu or Genjitsu the concept:

While working on this concept before jumping into any conclusion for why the anomaly or issue has caused. It states to collect the facts associated with the anomaly, process and the area, try to learn more in-depth details while collecting the facts.

It will Provide you necessary details to take concrete actions against towards the problem or anomaly and to avoid them in future from repeating itself.

The action will help reducing waste and improve process efficiency across the organization. To achieve best results organizations must work hard when implementing Gemjitsu or Genjitsu toward collecting the facts rather than jumping to the conclusion.

The Invisible Facts:

Linking the data gather process to 6M i.e., Man (persons or operator), Method (Process or Procedures), Machine (Equipment), Material, Measurement, Mother nature (area or surrounding) assist people in channeling the facts behind the conclusions or assumptions that people sees directly. Gemjitsu or Genjitsu method is good to uncover the hidden facts of the anomaly or problem.

Benifts of Gemjitsu or Genjitsu

- It uncovers hidden facts to take decisions

- Easier to convince people for decisions with facts in hand.

- It helps to reach the root cause of the problem

- Determine the size of scope of anomaly or problem.

- Rather than pointing out fingers to people or fault finding, it establishes trust and dialog between people.

Learning from the facts helps in improving the moral of people in relation with the problem. Providing standardization to the results or decision helps in stopping the problem from reoccurring in future. In simple words Gemjitsu or Genjitsu describes the unit that shows a anomaly or problem.

Third G of the 6G (see this definition) and to learn more, we invite you to have a look at our newsletter n°23: the 6G .

Managers and leaders can learn concepts of 6G and Gemjitsu or Genjitsu for understanding a realistic approach to take right decisions towards increasing productivity, reducing wastes and increasing profits, also to understand the way and practices of lean methodology.