Kanban(看板) or Kamban, a Japanese term that literally means "signal", "tag", indicates an element of the Just in time system for replenishing stocks as they are consumed.

Pull Concept:

Traditional or old method in production starts with production on receiving orders from customer and ends with dispatching of products this creates, natural push when everything is pushing downstream. This method results in generation of wastes down the stream. Biggest drawback is inventory in line is necessary for smoother production.

Kanban is based on pull concept with which the scheduling and control is established for upstream production stages stream lining production. It creates feedback loop in production stages from down to upstream. When pulling something it requires force as pulling WIP material from previous production stage. Kanban results in a production system that is highly responsive towards customers and their demands.

Kanban (Kamban) Supermarket or Scheduling:

When you visit a supermarket, small quantity of every item can be found at a defined location across supermarket with a fixed and limited space allocated. Customers comes, visually select items and start picking up items in their cart. After purchase supermarket warehouse prepares and daily replenishes of the exact items that has been sold.

Kanban (Kamban) scheduling or supermarket in manufacturing works in the similar way. Its elements are:

- Generating points for stock

- A signal at each material withdrawal

- Immediate feedback loop system

- Frequent replenishment of stock

Kanban (Kamban) card:

Kanban card contains information such as work, timeline, responsibility, status, description etc.

In particular, the Kanban card is a card that recalls the downstream production. A code is produced or moved only if there is a kanban card that requires it. It is a communication tool for the transmission of orders to be launched in production and the withdrawal of material between the different production phases, according to the Just in Time logic.

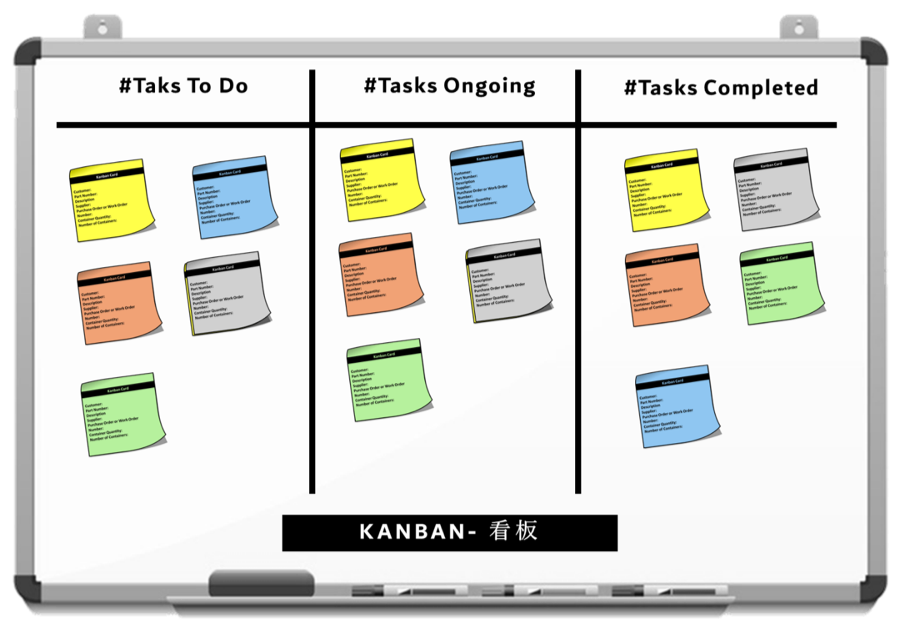

Kanban (Kamban) Visual Board:

Kanban Visual Board is a method for visualizing workflow and provides a scheduling system in production. It uses Kanban cards in following visual manner:

- #Taks To Do

- #Tasks Ongoing

- #Tasks Completed

Benefits of Kanban (Kamban):

- Preventing over production

- Developing flexibility in production

- Reducing waste

- Minimizing wait times

- Reducing inventory levels

- Saving resources by streamlining production

- Reducing floor space usage by stock pile up

- Increases Output

To check your stocks and flows, consult our Lean Kanban training program.