Kobetsu Kaizen is a Japanese (個別改善) term which means ‘targeted improvement’ or ‘Focused Improvement’. It is one of the 8 pillars of the TPM system. Kobetsu Kaizen approach is adopted to create a loss structure or loss tree for the equipment and its performance is improved through kaizen Initiative.

Features of Kobetsu Kaizen:

- Attacks difficult problems

- Loss cutting approach not Cost cutting

- Benchmarking approach

- Increase VA (Value Added) Targets.

- Project Teams Organization

- Long term Plans for benefits

- Continual Improvements through Kaizen

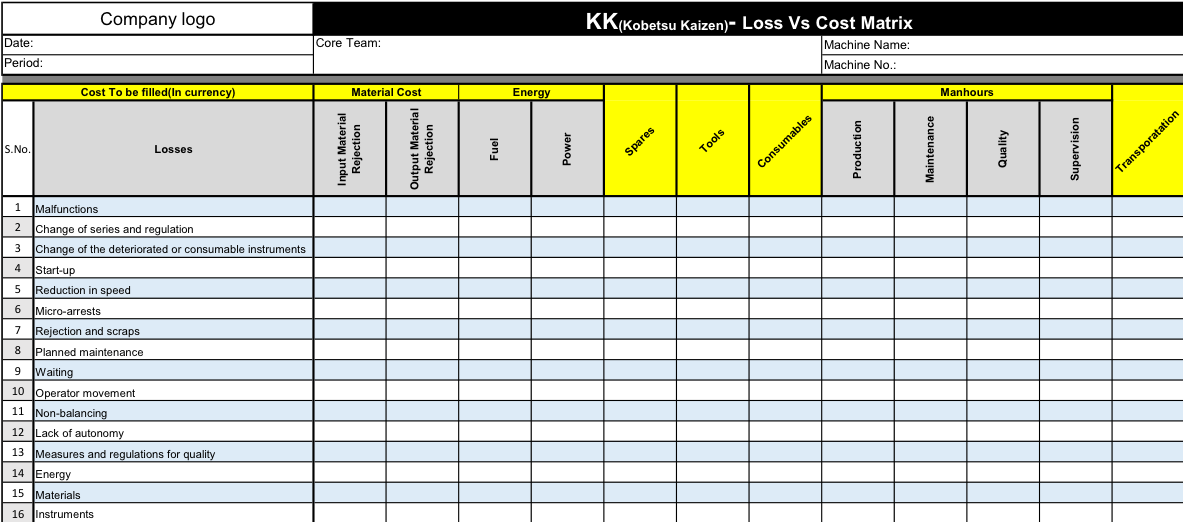

Kobetsu-Kaizen can be used in such cases to the improve an individual equipment or line for more efficient production systems. It attains such focused improvement by challenging the team to achieve zero losses. There are 16 types of losses which should be analyzed during a Kobetsu workshop. Thus, helping an organization to improve on all of the main losses revealed by Pareto. it realizes the zero loss situation in such as an equipment failure and product defect & that affect ultimate production efficiency situation.

To learn more on this topic, follow the training course ‘Lean TRS Kobetsu‘.

The method for the implementation of ‘Kobetsu Kaizen’

- Selection of model equipment: Identify an equipment or a line which needs focused improvement. (Based on Anlysis)

- Organization of a project team: Create a team of employees related to the model equipment or line. A member of management from the team should be made the team leader.

- Grasping and confirmation of 16 major losses: The team must find and analyze all the 16 major losses to detect the main losses.

- Theme and Promotion Programs: Theme based decision in which promotional program has to be prepared.

- Project activities: Different tools that can be used for the ‘Kobetsu Kaizen’ activities are like Failure Analysis methods, IE methods, PM analysis (for chronic losses) etc.

- Standardization: Standardize the activity performed so that process cannot deviate after implementation

- Horizontal Deployment: After Standard process is establish horizontal deployment must be applied to similar facilities equipment and manufacturing process for enhancement of OEE.

Benefits of ‘Kobetsu Kaizen’:

As established earlier, ‘Kobetsu Kaizen’ is a ‘focused/ targeted Improvement’ process. This provides a team-based structured approach to eliminate specific loses identified in any operation in the system to reduce waste and improve quality, cost, etc. It provides quick and sustainable results.