Lean Manufacturing is a combination of the proven methods which have the goal of increasing the concentration of value added in each work process.

Lean manufacturing optimizes the flow of information and materials, improves productivity and eliminate wastes from processes.

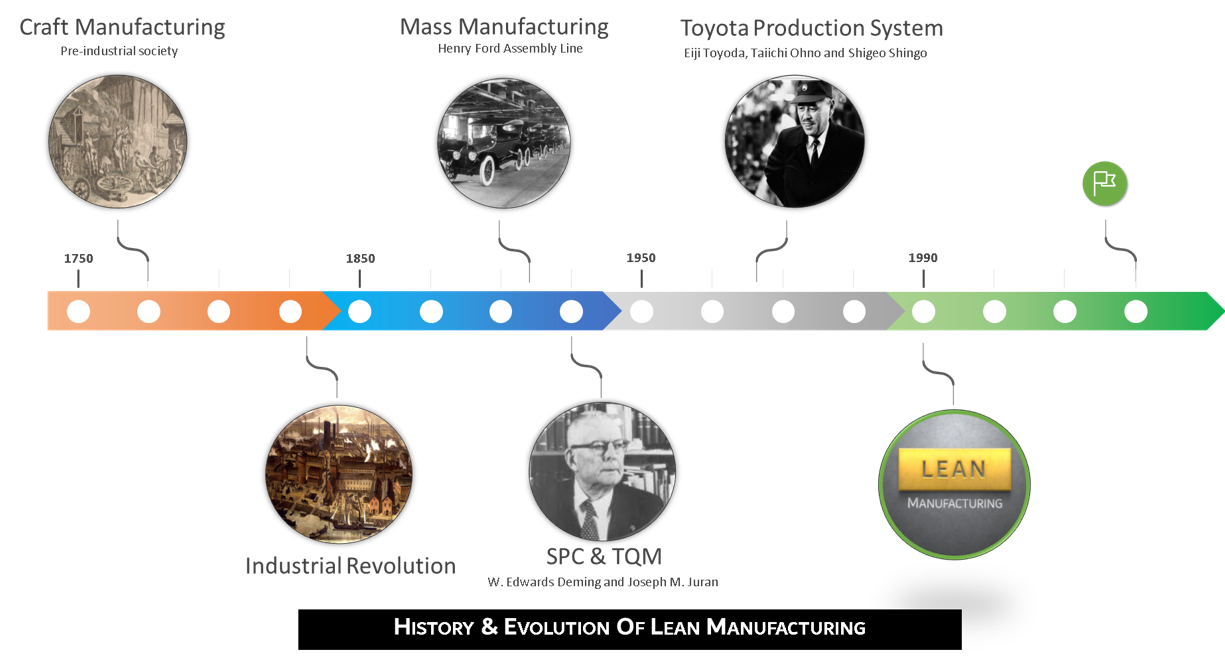

Lean manufacturing History:

Lean Manufacturing is an organization model which first appeared in Japan after the 60s. Large part of the body of work of the methods which are part of Lean Manufacturing was developed by the Toyota Motor Company thanks to the work of its historical vice president Taichi Ohno.

During the early phase of development, Lean Manufacturing availed itself of the studies of Dr. Edward Deming (USA) on quality and organization; these studies were diffused in Japan during the reconstruction of the country following World War II.

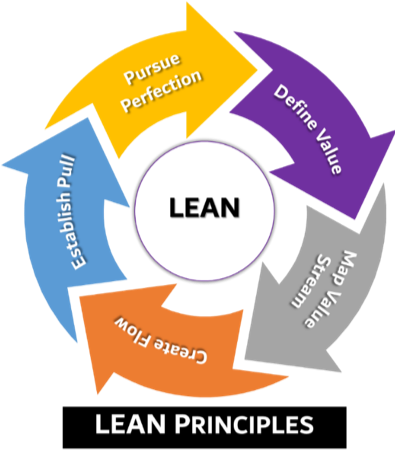

Lean manufacturing principles:

Five key Principles of Lean in an iterative design that are:

- Define Value

- Map the value stream

- Create Flow

- Establish Pull

- Pursue Perfection

Classification of wastes:

Three types of Waste can be described as

Adding Value from Lean?

What is Value added and what is not?

Value Added activities means activity or operations performed are required by the customer and essential for product.

Non-Value-Added but necessary activities are those activity or operations performed are not required by the customer but essential for product.

Non-Value-Added activities are those activity or operations performed are not required by the customer nor essential for product.

Lean Manufacturing focuses on improving value added activities and eliminating the non-value-added activities.

Lean manufacturing approach:

Within Lean Manufacturing there are 2 distinct methodological approaches: Just in Time and Total Productive Maintenance.

These 2 models refer respectively to the 2 fundamental contexts of the production of value; the context where it is man with his own hands to produce the value refers to the Just in Time method, while the context where the structures produce the value refers to the TPM method. The JIT and TPM methods are assisted by a series of principles and concepts which constitute the basis of the attitudinal approach which Lean Manufacturing requires.

Lean manufacturing has been adopted and practiced by many leading and developing organization across the globe with only one requirement “Everyone must be involved without exception”.