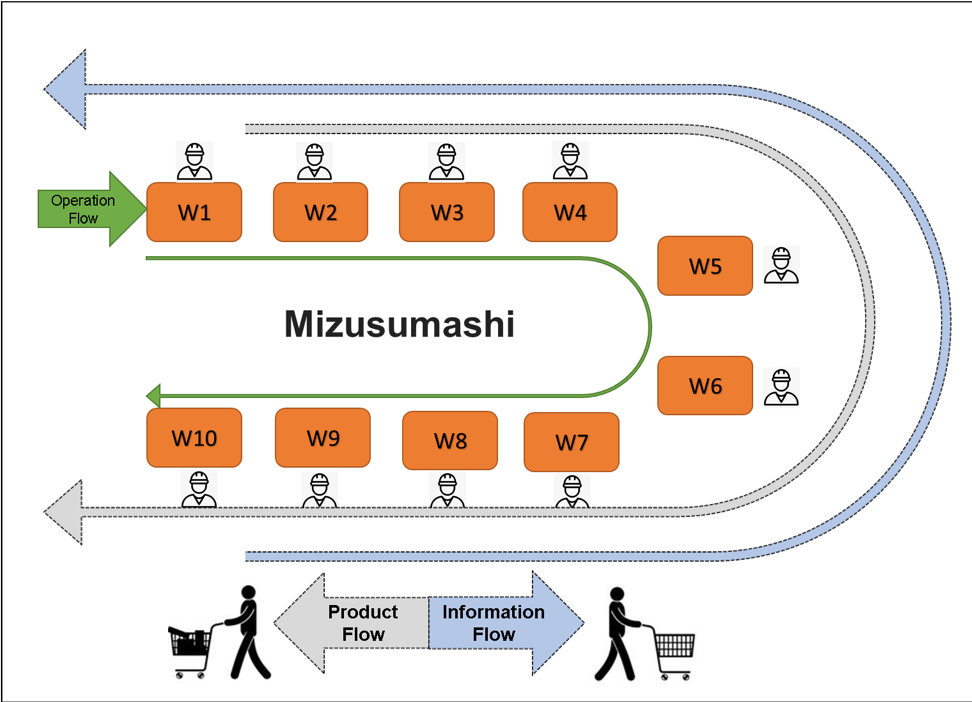

Japanese term which designates an operator-supplier also known as water strider or water spider in english, the «Mizusumashi»,

Main task under Mizusumashi or Water spider to ensuring materials are supplied where and when they are needed. It prepares a cart of orders for the operator of the assembly, so that the operator can concentrate on his own value addition and contributing to overall higher productivity.

Excess Motion, Inventory and transport is also a waste. Mizusumashi help to controlling it by concentrating on requirements at the moment.

Mizusumashi Methodology:

- Establishing Water spider or operator-supplier position.

- Set roles, responsibility and goals aligned with Mizusumashi purpose.

- Remember in Mizusumashi Water spider’s or operator-supplier’s role is very important as their aligned goals is also to reduce the process lead time and reduce waste.

- Water spiders are responsible for the replenishment of material at point of use, transporting the materials from Lean supermarkets to production area. They are also responsible for the information flow that origins all the replenishments.

- Create routes and time table for the Mizusumashi supply run which will establish a standard process. Under Lean methodology Supermarket and Milk run.

- Do not let the production line stops, as Mizusumashi system can be best utilized under Kanban system.

- The route must clear and have some space without any stoppages for smooth flow.

- Water spiders should coupling the empty cart collecting the respective Kanbans.

- Water spiders must know the processes of the operations they are supporting. This knowledge helps them identify any inefficiencies.

Mizusumashi Benefits:

- Eliminates idle operations.

- Reduces waste of Motion and transportation

- Improve productivity

- Decrease WIP stock pile at different stations.

- Up to date WIP stock status.

A best aspect of a Mizusumashi is that it is system-centric not person-centric tool in the sense that all of the work revolves around the efficiency of the system. This matters as it is not acceptable for the Mizusumashi to do a few half-empty rounds, not delivering material to all work stations, servicing those few stations in need.

To optimize your supply circuits, please consult the training program on Mizusumashi.