A One Point lesson or OPL is a single-point lesson that shares important information in a short visual format representation.

This type of lesson is based on a single topic which is generally drawn on a single paper of A3 or A4 format.

A one-point lesson is: clear, simple, and easily understandable for everyone. The lesson transfers topic-related knowledge to a team or a workplace user. A One Point Lesson is designed by an experienced working team, team manager, or shift supervisor for quickly conveying information and instructions to a team or colleagues.

It is meant to fast train people on a not complex process. It is a great tool to transmit operating knowledge and technical skills, it can bring examples of problems, and present concrete cases of countermeasures. It gives the person that reads it, ownership of the processes represented and helps also boost the motivation to actualize the lesson.

A One point lesson must be placed in the most visible areas of work near where it is necessary, such as work stations, work meeting areas, display boards, etc. It shares key learnings and creates a common understanding of the systems and standards that must be applied by the team or the person that work in that area.

More details:

- A One Point Lesson is more visual and lesser text representations i.e., 80 percent pictures and 20 percent words.

- In lean methodology the OPLs are often used in Kaizens, TPM, 5S, JIT, Safety, etc. as usage of machines, checking oil levels, performing autonomous maintenance, dos and don’ts, and many more.

- It is utilized in other fields of use such as:

- Quality applications: Identifying defects and defective products etc.

- Inventory applications: Determining quick fast inventory levels check with visual representations.

- Inspection applications: Define Inspection locations correct method of instrument utilization etc.

- Maintenance applications: For regular checks of equipment and machine for better output.

- Equipment operation applications: Using one point lesson for teaching procedures of loading and unloading of material, changeover guidelines, machine cleaning, troubleshooting, etc.

- It can also be introduced in weekly meetings, as quick lessons for new employees, and as a reference for regular checkpoints.

- In a short answer, one point lesson is made to provide to-the-point immediate knowledge to the people with their minimum effort.

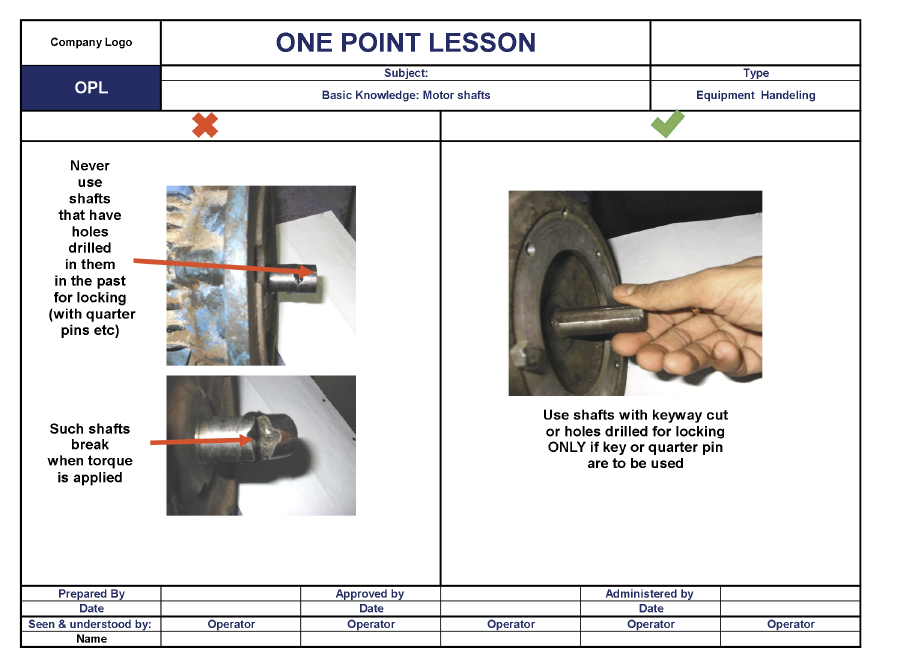

One Point Lesson Example