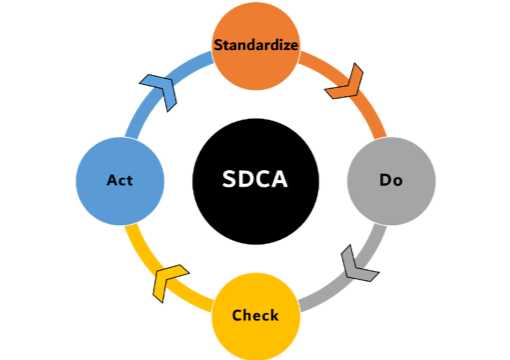

SDCA is a lean tool. This is acronym for Standardize, Do, Check and Act.

What is SDCA Cycle?

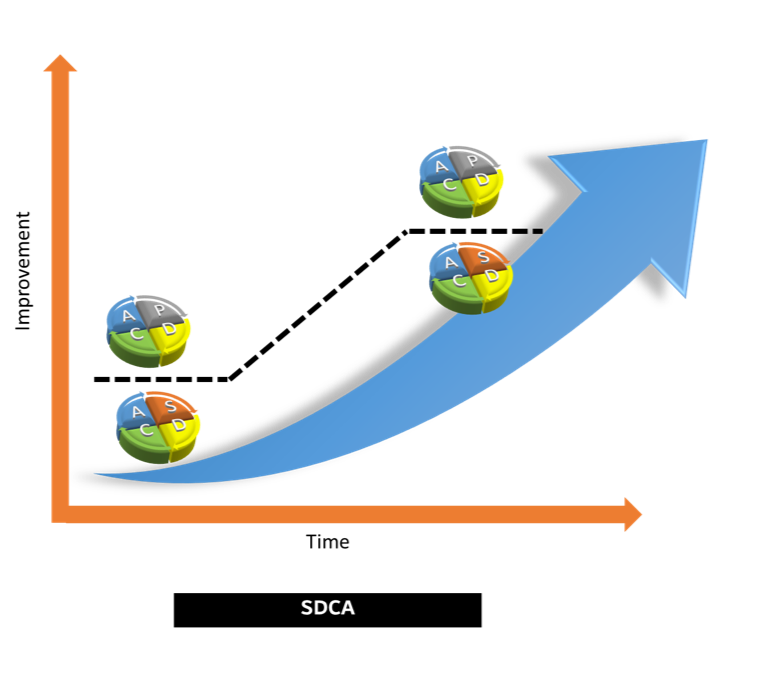

There are 3 Cs in Lean Cycle: SDCA, PDCA, EDCA. In SDCA Cycle the management first establishes the standard before preforming PDCA Cycle. The main goal of these cycles is to produce standardized and improved products. The SDCA cycle is an important part of an organization that values perfection.

When an organization should apply SDCA Cycle?

A non-standardized process fails to provide desired outcome consistently. This also concludes that the process is not stable. In such case, organization needs to establish the standard, to stabilize the process and improve it. To create the standard, you can use SDCA.

Steps to apply SDCA:

Hosotani (1992) defined standardization as “The systematic activities of establishing and utilizing standards.”

- S - Standardize: The SDCA cycle starts when a member of the organization has an idea to establish standard for a process or an operation. After discussing and reaching to an agreement to next step is taken to standardize. To establish the standard, the team needs to collect knowledge to meet the customer needs. It is important to remember the goal is to provide the customer with the highest quality product (or service) at the lowest cost and in a shorter time. Most important part is that everyone should adhere to the standard to achieve desired consistency in the outcome. A team is created related to the process function. A team leader is appointed who writes the standard. Standardization provides a clear guidance of what is to be done and how it is to be done.

- D - Do: This step refers to the application of the standard to its respective operation.

- C - Check: After the standard is applied, it needs to meet the expectations of the outcome. It is done in this step. Thus, check means to verify the effectiveness of the standard applied.

- A - Act: This is the final step after which the standard becomes a benchmark for improvement. In this step all the documentation and training necessary is completed to make the standard official and now the existing standard for the process.

Benefits of SDCA

- Minimize Losses.

- Sustaining improvements becomes easier.

- Reducing time wastages

- Creates Benchmark for improvement.

- Can view level of implementation for improvements and standards.

- Sustains lean gains and develop lean culture.

After the standard is enforced and stabilized, PDCA cycle “Deming Cycle “can be used in order to modify this standard.