The Variation Mode and Effect Analysis, or VMEA, is a systemic study of the Variability causes of a Process and the means to prevent them.

VMEA is without a doubt the most important tool of the “Analysis” Phase. All the preceding activities flow into the VMEA. The essence of what comes next depends on it. The Six Sigma tools are powerful especially when they are used in their complementarity.

VMEA is the center or the “pivot” of the project. Almost all the successful DMAIC projects have included a well-conducted VMEA analysis.

Such analysis highlights the points which require your attention, even those of which you are not even aware.

Variation Mode and Effect Analysis (VMEA) method can be described under the purview of statistical engineering. It helps during the product development stage prioritizing on variation reduction.

When taking about VMEA vs FMEA the difference can be established as FMEA uses the Idea of Failure and on the other hand VMEA uses the Idea of Variation. When Key characteristics directly relates variation VMEA is a best solution to provide better results.

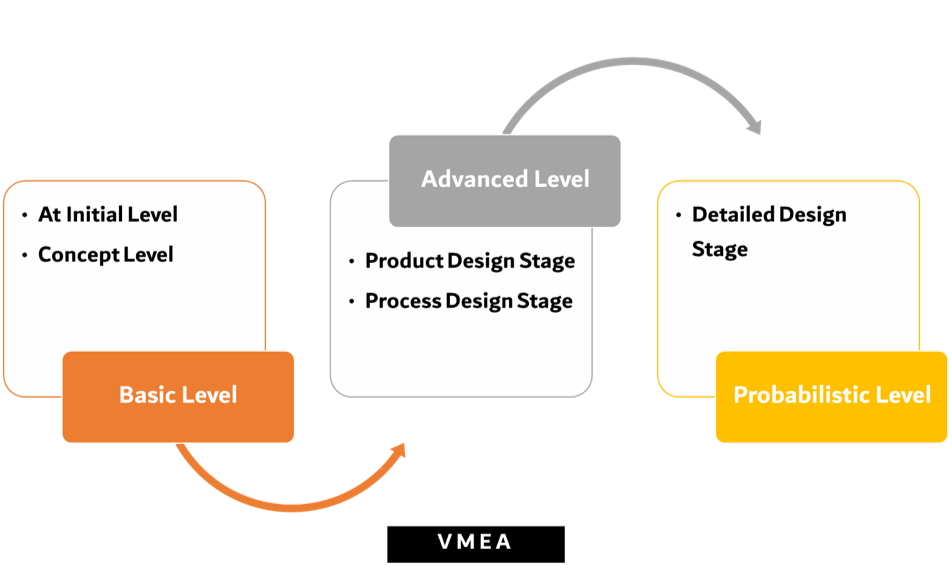

Levels of VMEA:

- Basic Level

- Advanced Level

- Probabilistic Level

VMEA Process and details:

- Development of a cross functional team

- Collection of data in the form of dimensions, Tolerances, Parameters etc.

- Identifying the main characteristics of products and process

- Distribution of main characteristics to smaller components

- Identifying factors affecting those smaller Components

- Analyze the coefficient affecting Main characteristics

- Calculating the variation Spread or size by using standard deviation.

- Determining the Risk and Prioritization of the risk.

- Other tools like ANOVA etc. can be used for in-depth analysis.

- Determining the factors affecting Safety

- Deployment and study of results

VMEA highlights the sources that needs control or causing variations. VMEA should be used in such case where results are difficult to obtain, other related cases. That is a type of benefit using VMEA Process. At basic level or concept level VMEA can be initiated with the Idea using experience and studies conducted.

A key factor of using the VMEA means that critical product characteristics are identified. To achieve best results VMEA should be performed with a cross-functional team and their combine knowledge.

The savings in terms of time and energy can be considerable!