We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture

Are you a professional lean trainer ? Do you want to receive new business opportunities ? Join for FREE our global network Register Here

Lean Training - Maintenance Audit

Run a maintenance audit to assess the company maintenance dept.

Where efficiency and productivity are paramount, a maintenance audit plays a pivotal role in ensuring operational excellence.

This process, which involves a thorough examination of maintenance practices and procedures, is critical for companies looking to optimize their performance and minimize downtime.

By conducting a maintenance audit, organizations can identify areas of improvement, streamline their processes, and ensure compliance with industry standards. Moreover, the utilization of maintenance audits helps companies maintain a safe working environment, reduce the risk of costly equipment failures, and ultimately, safeguard their reputation in the market.

Objectives

The main goal of this module is to run a maintenance audit at your whole plant or parts of it. Beside this first important goal your collaborators will learn to:

- Grasp the fundamentals underpinning operational performance through optimized maintenance.

- Master measuring maintenance service performance.

- Learn to structure your own benchmarking program.

- Identify and assess risks.

- Learn how to set improvement goals from a maintenance audit report.

- Learn how to set-up an action plan after a maintenance audit report.

- Apply the learnings from the maintenance audit report, either through a work group or with the help of an expert.

What is this training about

A maintenance audit is a comprehensive examination of the foundational parameters of a function executing a process within a specific area of interest. By conducting a maintenance audit, we assess all critical parameters of the function against a benchmark derived from best practices employed by top-tier companies.

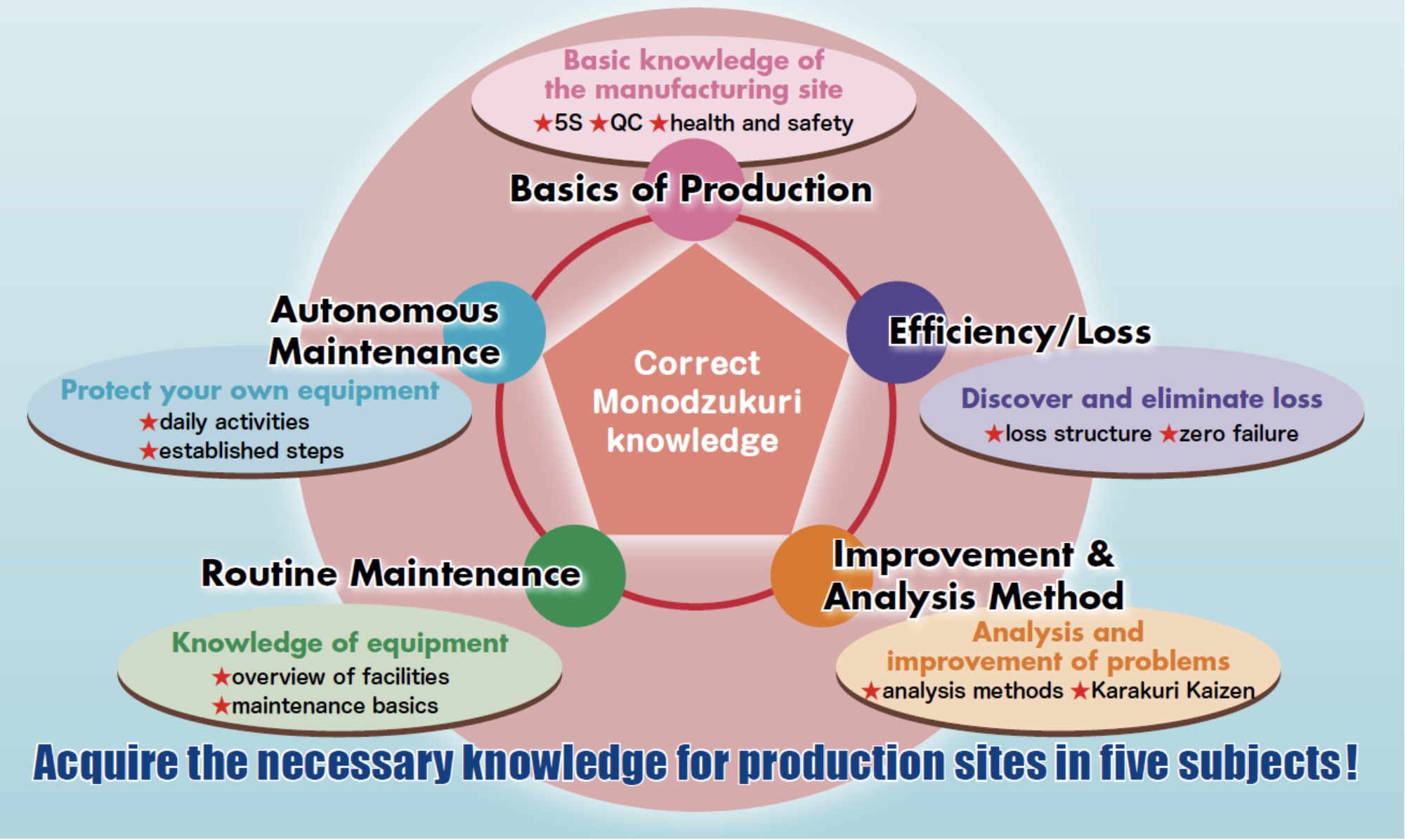

In the context of this module's maintenance audit, the benchmarks are based on the Total Productive Maintenance (TPM) philosophy. The specific areas of focus for this audit include:

- Basic requirements of the TPM

- Status of TPM promotion

- Focused Improvement

- Autonomous Maintenance

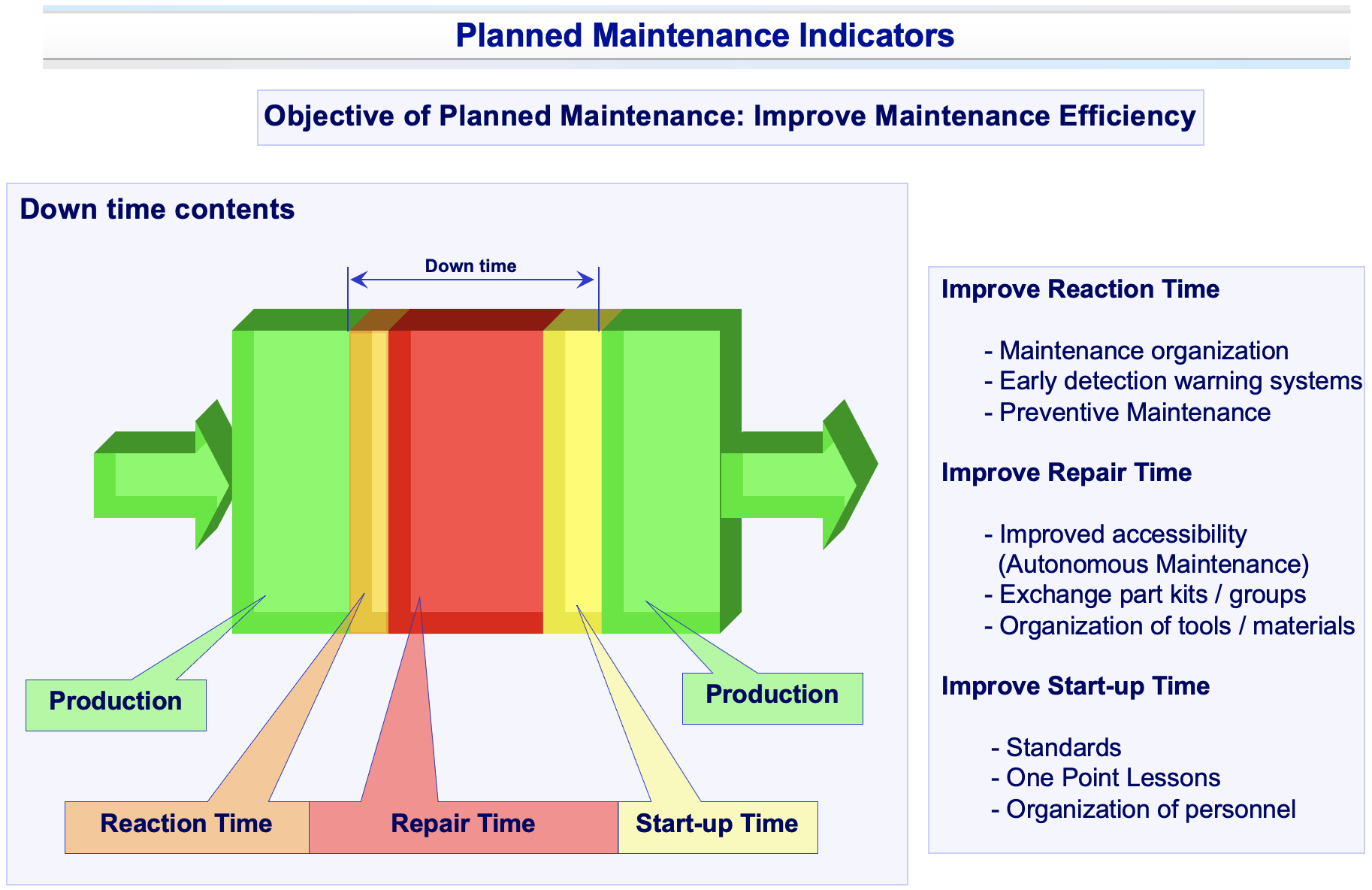

- Planned Maintenance

- Quality Maintenance

- Education and Training

- Safety, Health, and Environment

- Early Management

- Improvement of Administrative and Indirect Departments

This module allows for the flexibility to conduct the audit on all 10 pillars or a subset of them, based on the specific needs and priorities of the organization.

Why your company have to do this training

To enhance your plant's performance, it is essential to optimize maintenance in the following three critical areas:

- Plant Equipment Standard Conditions

- Maintenance Organization

- Maintenance Team Competencies

Without measuring your plant's status in these areas, it's impossible to make improvements. A maintenance audit serves as a powerful tool to assess your maintenance capabilities and status, enabling you to identify areas for improvement and implement effective strategies to boost your plant's performance.

What your collaborators will be able to do after this training

Following this maintenance audit, you will gain a clear understanding of the specific improvements your company must undertake to advance to the next level.

The comprehensive report we provide will outline a detailed action plan, enabling you to effectively guide your maintenance team's efforts.

Additionally, this maintenance audit serves as a valuable opportunity to learn or reinforce your knowledge about the TPM, ensuring your organization is well-equipped to implement best practices and achieve operational excellence.

Participants

Date & Duration

Locations & Fees

Information request

Detailed training program

Day 1

- Presentation of the principles of the maintenance audit

- Review and explanation of the necessary data for the realization of the maintenance audit

Day 2-3-4-5

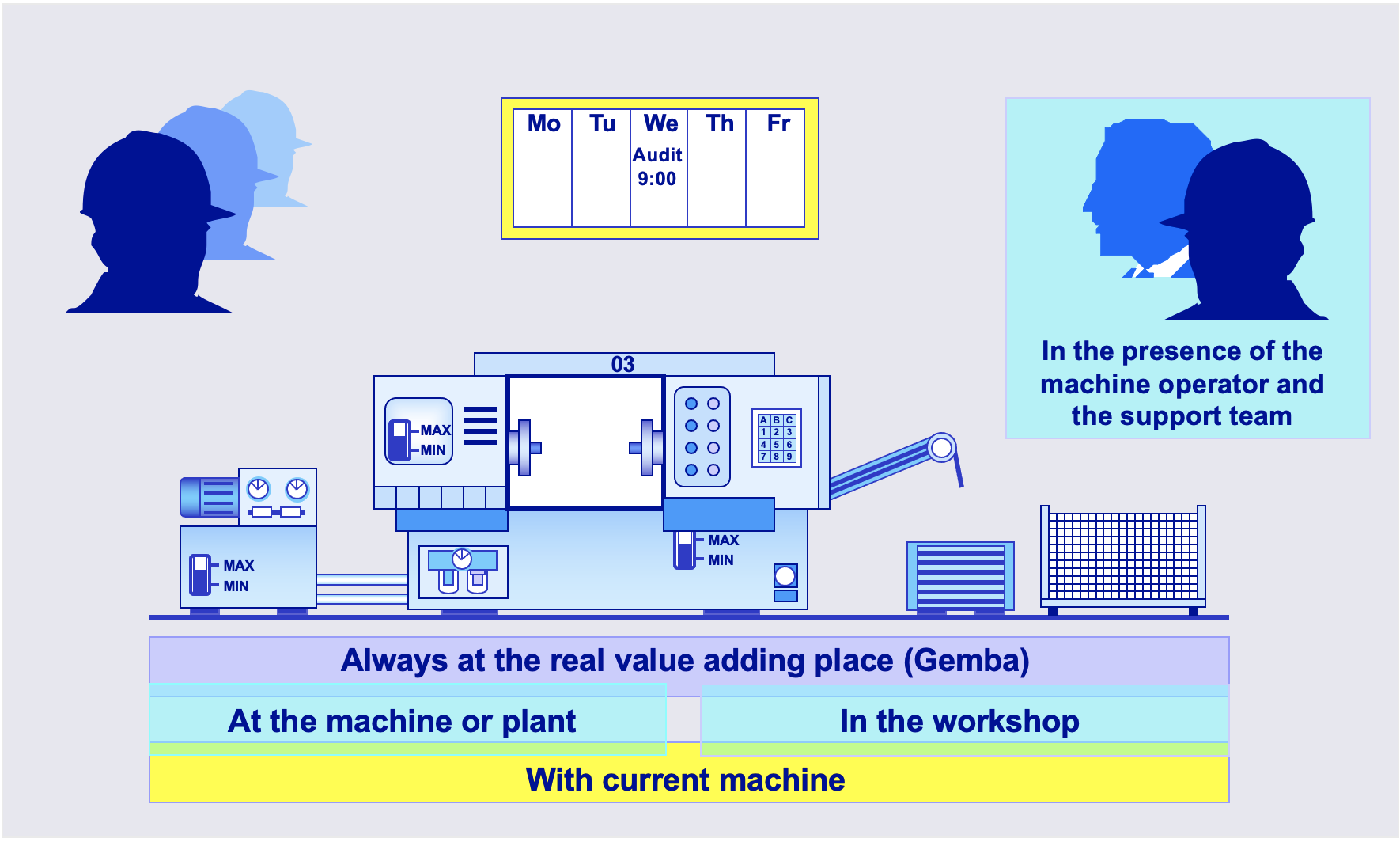

On site realization of the maintenance audit through:

- Validation of the relevance of the data collected

- Calculation of the 12 EMYL® percentages and global performance benchmark

- On the shopfloor evaluation of the maintenance service quality

- Analysis of the auto-evaluation of the maintenance dept. practices

- Presentation of the stakes and challenges of the maintenance dept.

- Preparation of a complete report (1 day outside the location)

Day 6

- Common definition of the progress plan/director scheme for the next 2 to 3 years

Ask to be guided on your training choice by an experienced consultant

We offer a 30-minute free call. Our support offer is real and our consultants will give their best so that the advice is of maximum use to you; it will be up to you and only to you to ask about any additional paid support; we will not ask for anything.

Guarantees:

- This consultation does not hide any attempt to sell.

- No attempt to sell will be made

- We will not use your data for commercial purposes

- All your information will remain confidential

This type of consultation is carried out via the internet and through the Zoom application.

To reserve your consultation fill out the form below, you will receive by email a response of acceptance and confirmation of the consultation session.

Mario Mason

Lean Senior Consultant

Please follow the instructions to schedule a time with me. It's quick and easy.

Thank you.

If you have any questions or uncertainties about this training, please submit them using this form.

We assure you that we will provide a response within 24 hours if your inquiry is submitted between Monday and Thursday.

The Kaizen Coach Team