Japanese word Gembutsu or Genbutsu (現物) literally translates as ‘real object’; here this means the equipment, the material or every other visible object.

In Japanese ‘Gen' (現) means original, real, primitive and ‘Butsu’(物) means thing, object, matter.

There are total 6G principles (Gemba, Genbutsu, Genjitsu, Genri, Gensoku and Genten) which are used for solving problems in Kaizen. Gembtsu is Second G of the 6G (to learn more, we invite you to have a look at our newsletter n°23: the 6G) .

Commonly used three G are Gemba, Genbutsu and Genjitsu, when used in combination together form extremely strong system for continuous improvement in an organization.

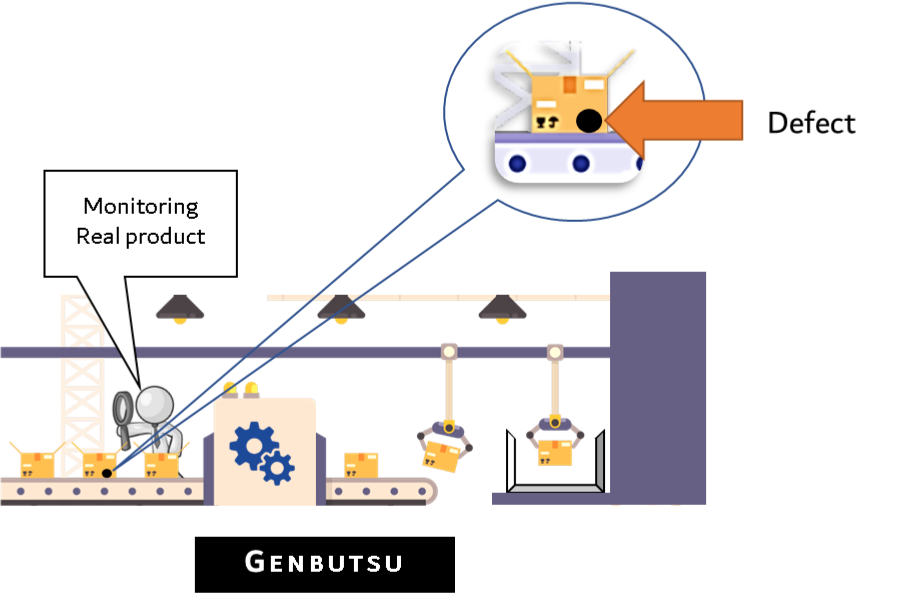

Genbutsu allows organizations to have their attention on facts and not only on reports. The management needs to take closer look at the actual final product to get a glimpse of what the end result of the whole manufacturing process looks like. It is easier for an organization to obtain actual details of a problem with the help of combination of facts and understanding of the product.

Besides the final stage, it is advised to monitor the product at every step of its manufacturing process. This helps to attain a better understanding of the process at each step of manufacturing. Also, it helps to see where and how the value gets added in different steps of the manufacturing process allowing to eliminate expensive and time-consuming steps. If these steps don’t add value to the customer specifications for the product it is considered as waste.

Such kind of waste can be missed in a report. Thus, to really trace the value added in a product, the organization needs to understand every stage of its manufacturing.

How to implement?

Genbutsu is very easy to implement. It doesn’t need any special training. Instead, the managers need to spend more time on shop floor where product is being manufactured. It helps to collect more facts by observing the process and communicating to the workers on the shop floor. Once found, problem can be approached any way the manager seems fit as there is no specific strategy. These observations can be either noted in writing or inform of pictures etc.

Benefits

Genbutsu helps to reduce or eliminate waste. These improvements lead to a more efficient and profitable workplace.