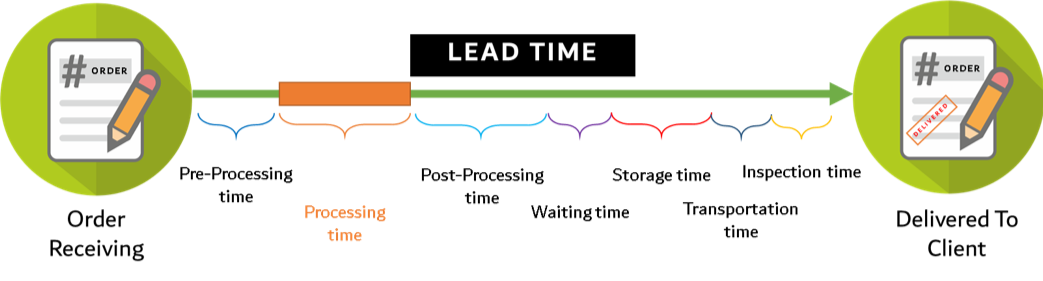

Lead time can be defined as time needed to meet a customer’s request or time it takes from receiving of an order till its fulfillment to the client.

Lead time more details:

It is a parameter that characterizes a supply chain at different levels. It is also called ‘crossing time’ (example of an order) or "response time".

Often lead time means the time needed by a company to meet a customer’s request (or customer lead time). The shorter the time, the faster and more flexible the company is in satisfying the customer.

You can talk about lead time referring to the reaction time of a company compared to the fact that the customer:

- request a new product: time to market

- place an order for an existing product: time to order.

The term is commonly referred under in supply chain management, project management, and manufacturing.

Lead Time is a fundamental concept of Lean and corresponds to the time needed to produce a product; from the entry of the raw material up to the shipment of the finished product.

Lead time Consists of:

- Preprocessing Time: Time taken to understand Processing requirements.

- Processing Time: the time required to manufacture or produce.

- Postprocessing Time: the time it takes to register the produces good in inventory or next process in line.

- Waiting time: The Idle time of process waiting for its requirements to fulfill before start.

- Storage time: The Idle time of product or stock waiting for its requirements to fulfill to move to the next process in line.

- Transportation time: Time taken by moving of goods.

- Inspection time: Time it takes to for quality inspections or defects segregation to meet customer requirements.it consist of both internal and external inspections.

Lead Time vs. Cycle Time Vs. Takt time:

Lead time: Time needed to meet a customer’s request or time needed from receiving of an order till its fulfillment to the client.

Cycle time: Cycle time is the time needed to complete and operation.

Takt time: utmost limit of time to meet customer demand.

Lead time Methods to optimize:

- Optimize cycle time: Identify the value-added and non-value-added activities. Then improve the value-added and remove non-value-added activities.

- Reduce change over time

- Reduce waiting time

- Remove idle time

- Reduce transportation time

- Optimize inspection time

- Establish pull system or scheduling

- Adopt single or one-piece flow