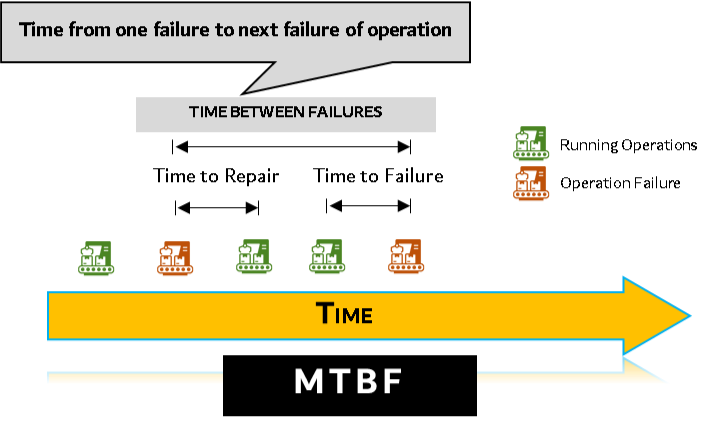

Indicators of reliability and maintenance frequency of the equipment. There are several different ones: MTBF « Mean Time Between Failure », or « Average Time of Well-Functioning » = Average time between two breakdowns.

Calculating MTBF:

The MTBF is calculated by taking the total time an equipment is running and dividing it by the number of breakdowns or failures that occurred over the same period. Total time an equipment is running can also described as Total uptime.

MTBF = Total uptime / no. of Breakdowns

Mean time between failures (MTBF) Larger the value better operational availability of equipment.

More details on MTBF?

Conducting an MTBF analysis helps your maintenance team to reduce downtime while saving money and working faster. Measuring MTBF is one way to get more information about a failure when it is going to likely occur and mitigate its impact. The impacts of machine failure can be significant. It leads to lost production and increased time spent on maintenance. Equipment Failure is a problem as it can be taken as a waste in terms of downtime or idle equipment. Getting to the root cause of failures and knowing everything about a problem is often the best way to solve it.

Relations with Availability of equipment?

Availability is one of the important factors contributing to the overall equipment effectiveness OEE of a plant. It can be described as Availability of an equipment for operation from total available time. It requires to calculate both (MTBF) Mean time between failures and (MTTR) Mean time to repair for calculating OEE.

(MTTR - see this term in the glossary)

Why MTBF?

MTBF helps you predict how long an asset can run before the next unplanned breakdown happens. This will help in stopping the unplanned stoppage of equipment by acting against the issues from which they occur. Mean Time Between Failures measures the predicted time that passes between one previous failure of a mechanical/electrical system to the next failure during normal operation.

Taking measures to improve MTBF and the reliability of your equipment can have a huge impact on your organization. For critical assets such as airplanes, safety equipment, and generators, MTBF is an important indicator of expected performance.