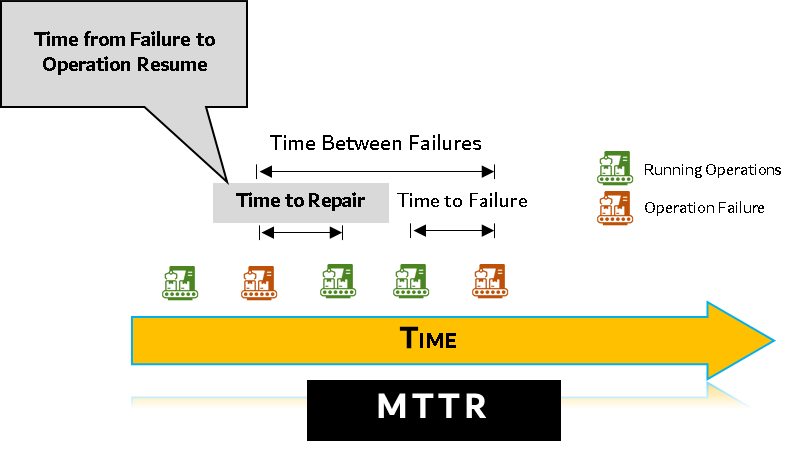

The MTTR « Mean Time To Repair » or Average Total Time of Repair or even average time to repair is a second indictor to measure the efficiency of the maintenance.

MTTR or Mean Time to Repair Methodology: The steps for MTTR start as the repairs begin and continues until the operations are up and running. Thus, it takes into consideration of time to:

- Inform the technician

- Identify the problem

- Repairing

- Testing time period

- Reassemble, alignment and calibration

- Test and start up the asset for production.

Calculating MTTR:

MTTR is calculated by dividing the total downtime caused by breakdowns (failures) by the total number of breakdowns (failures). In other words, it can be summed up as the time spent on the repairs divided by the total number of repairs performed. It helps an organization to check how well they can respond to unplanned breakdowns (Failures) and repair them.

MTTR = Total downtime due to breakdowns (failures) / Total number of breakdowns (failures)

This calculation takes into account that:

- Tasks are performed in a sequence

- Tasks are performed by trained employees

It is important to note Lesser the MTTR value better the equipment availability.

Relations with Availability of equipment?

Availability is one of the important factors contributing to the overall equipment effectiveness OEE of a plant. It can be described as Availability of an equipment for operation from total available time. It requires to calculate both (MTBF) Mean time between failures and (MTTR) Mean time to repair for calculating OEE.

(MTBF - see this term in the glossary)

Why MTTR?

When an equipment is under breakdown, it’s non-operational. Frequent breakdowns and prolonged downtime lead to lower equipment availability and equipment uptime. This results in bad business results. An organization leads to missed production deadlines, increased labor costs, loss of revenue, and a variety of operational issues because of frequent and prolonged breakdowns. Most organizations seek to decrease MTTR with an in-house maintenance team.

Understanding MTTR is an important tool for any organization because it needs efficiently tackling or respond to any failures and repair or any issues with your assets/equipment.