WCM or World Class Manufacturing is a concept based on operational excellence program in manufacturing or production facilities.

In today’s fast growing and competitive world, it is very important for an organization to have cost effective, waste free (Lean), efficient, flexible and innovative manufacturing practices. World Class Manufacturing (WCM) is structured and integrates itself to production or operations that is under all manufacturing processes across organization.

More details on WCM or World Class Manufacturing:

World class manufacturers tend to implement best practices, focus on operational efficiency, reducing wastage and creating cost efficient methods and also invent new practices as to stay above the rest in the competition.

Some of the methods and its requirements to start working on world class manufacturing.

- Implement 5S to keeping workplace organized and efficient.

- Implement Just in time and achieve best results towards zero inventory across organization.

- Implementing visual management to create visual and highlighted information system.

- Implement Lean Methodology and achieve best results towards zero waste across organization.

- Implement Total Productive Maintenance and have OEE more than 80%

- Implement Total Quality Management and achieve best results towards 100% customer satisfaction organization.

- Higher employee involvement by making Quality Circles, Multi skill employees with-in the organization etc.

Principle of WCM:

World Class Manufacturing Principle can describe as Follows:

Zero:

- Zero Accidents

- Zero Breakdown

- Zero Defects

- Zero Scrap

- Zero Waste

100%:

- 100% Customer Delight

- 100% Employee Motivation

- 100% Visible anomaly

- 100% Employee participation

- 100% OEE

Structural Representation of World Class Manufacturing:

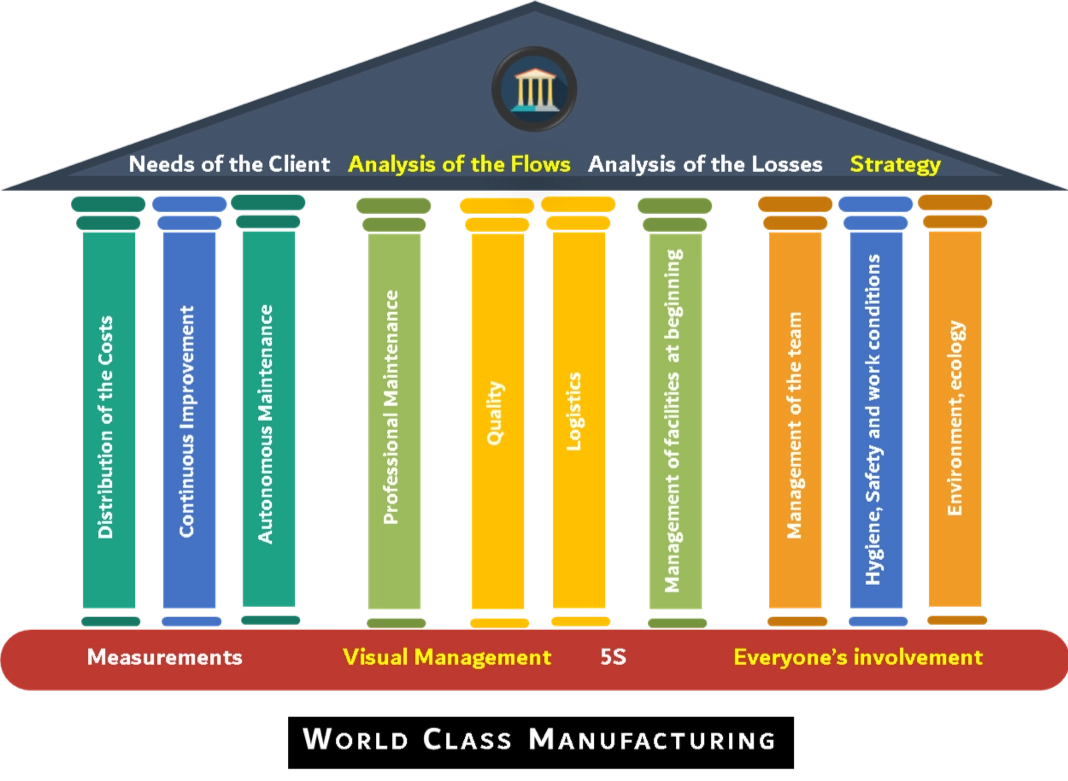

World class manufacturing is expressed graphically with the form of a Greek temple whose elements are explained as follows:

Baseline (The base of the temple):

- Measurements

- Visual Management

- 5S

- Everyone’s involvement.

Ceiling (The Roof of the temple):

- Needs of the Client

- Analysis of the Flows

- Analysis of the Losses

- Strategy

Strength Pillars (The 10 Pillars):

- Distribution of the Costs

- Continuous Improvement

- Autonomous Maintenance

- Professional Maintenance

- Quality

- Logistics

- Management of the facilities at the beginning

- Management of the team

- Hygiene, Safety and work conditions

- Environment, ecology