Indicators of reliability and maintenance frequency of the equipment. There are several different ones: MTBF« Mean Time Between Failure », or « Average Time of Well-Functioning » = Average time between two breakdowns.

The MTTR « Mean Time To Repair » or Average Total Time of Repair or even average time to repair is a second indictor to measure the efficiency of the maintenance.

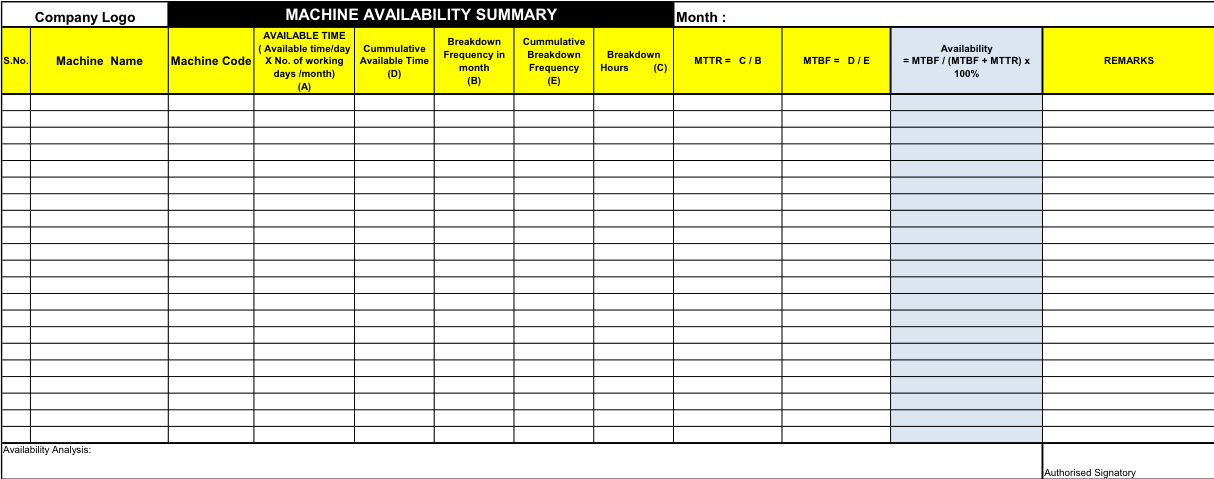

Calculating MTBF:

The MTBF is calculated by taking the total time an equipment is running and dividing it by the number of breakdowns or failures that occurred over the same period. Total time an equipment is running can also described as Total uptime.

MTBF = Total uptime / no. of Breakdowns

Mean time between failures (MTBF) describes the expected time between two failures for a repairable system.

Calculating MTTR:

MTTR is calculated by dividing the total downtime caused by breakdowns (failures) by the total number of breakdowns (failures). In other words, it can be summed up as the time spent on the repairs divided by the total number of repairs performed.

MTTR = Total downtime due to breakdowns (failures) / Total number of breakdowns (failures)

More details on MTBF and MTTR?

To know more about MTBF (Mean Time Between Failure) and MTTR (Mean Time to Repair) see our Lean dictionary.

(MTTR - see this term in the glossary) (MTBF - see this term in the glossary)

Identifying Availability or Uptime Percentage of equipment?

Availability can be described as “The proportion of time for which the equipment is able to perform its function” Availability is one of the important factors contributing to the overall equipment effectiveness OEE of a plant. It requires to calculate both (MTBF) Mean time between failures and (MTTR) Mean time to repair for calculating OEE.

Availability = MTBF / (MTBF + MTTR) X 100%

Converting it to percentage shows the equipment running percentage out of schedule running hours designated for the equipment.

Why it is necessary?

Maintenance Teams can use these tools to perform:

- Repair vs replace analysis

- Whether they need to invest more resources into training maintenance staff

- Do they need to upgrade operating procedures and workflow?

- What spare required in hand and why?