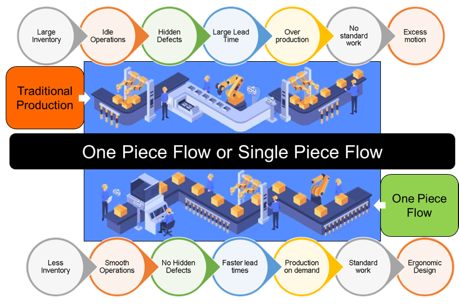

The term One Piece Flow or Single Piece Flow indicates items proceed through the various stages of production one «piece at a time».

In companies that start to adopt the Lean paradigm, gradually, they move from an organized production in batches (push), typical of the production philosophy of mass production or traditional production, to a pulled-flow production (pull)Kanban.

Batch processing or traditional production usually isn’t efficient, the customer usually has to wait until the next batches produced to get their required product. The processes designed in Just in time methodology and cellular manufacturing uses one piece flow.

The Lean philosophy aims to minimize stocks, including inter-operational ones, because they hide the problems, both related to the machinery (16 losses), and related to labor (not respected standard cycles, imbalances in activities between different operators). To produce one piece at a time means to have optimized the whole production process, from the first to the last phase. (Kanban(pull), Just In Time methodology, Cellular Manufacturing and 16 losses – see these terms in the glossary)

Advantages of one-piece flow:

- Increase value addition to product and decrease non value added activities.

- Eliminates Over Productions and enables production on-demand

- Reduce inventory by eliminating huge raw material requirement, WIP stock pile between the processes and finished goods as it was pulled against customer demand.

- Movements of people and transportation of goods decrease drastically due to pull system.

- Maximize floor space utilization.

- Easy defects identification and segregation.

- More safer environment due to optimized layout.

- Reduced Lead times

- Ergonomically efficient for operator can work more efficiently with lesser fatigue.

One Piece Flow or Single Piece according to Lean philosophy is a very good tool to remove Muda (無駄, waste), Mura (斑, unevenness), and Muri (無理, overburden) – see these terms in the glossary.

One piece flow makes the production process flow continuous and smooth, single piece at a time, creating a steady workload for all operations.

One Piece flow requires:

- Working Kanban (Pull) system

- Cycle times must be repeatable and in sync or scaled to TAKT Time.

- Equipment used must have higher uptime

- Shorter changeover times

- Processes must be able to consistently produce a good product